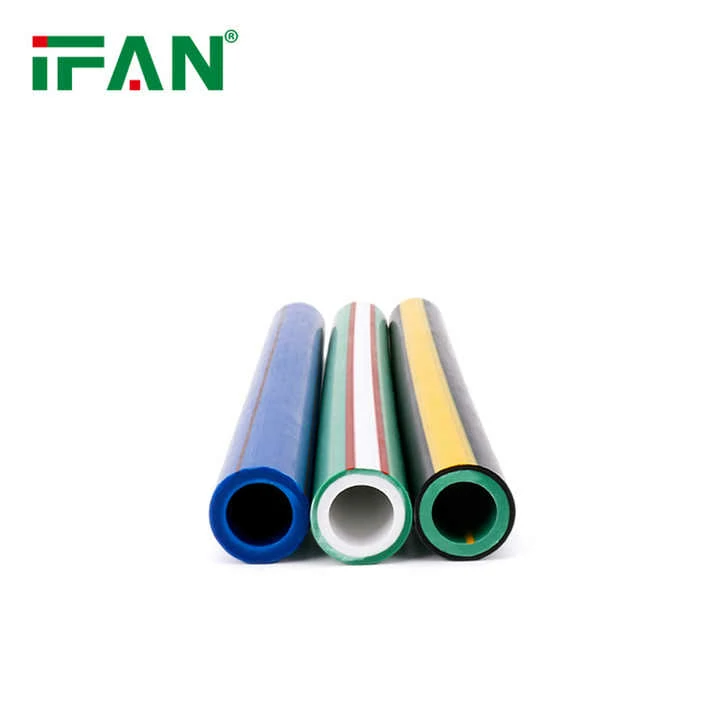

Introduction to PPR Pipe Colors

PPR pipes come in various colors, including white, gray, and green. The green variant is specifically designed for oxygen-barrier applications in heating systems. Unlike standard PPR pipes, green-striped versions prevent oxygen diffusion, protecting metal components from corrosion. This color-coding helps professionals quickly identify pipe functions during installation.

The Science Behind Green PPR Pipes

Green PPR pipes contain an ethylene vinyl alcohol (EVOH) layer that blocks oxygen penetration. This layer is co-extruded with the polypropylene material, creating a durable composite structure. The green stripe serves as a visual indicator of this advanced construction, ensuring proper system compatibility.

Oxygen Diffusion and System Protection

In closed-loop heating systems, oxygen infiltration accelerates corrosion in boilers and radiators. Green PPR pipes reduce oxygen permeability to <0.1 mg/L per day, meeting DIN 4726 standards. This extends equipment lifespan by preventing rust-induced failures.

Applications in Heating Systems

These pipes are essential for radiant floor heating and central heating networks. For example, German households using green PPR pipes report 30% fewer corrosion-related repairs compared to non-barrier pipes. Their thermal stability also suits high-temperature environments.

Comparison with Standard PPR Pipes

Standard white PPR pipes lack oxygen barriers, making them unsuitable for heating systems. Green variants cost 5–10% more but offer long-term savings by preventing system damage. Contractors must select the correct type to avoid premature failures.

Installation and Compatibility

Green PP-R pipes require fusion welding at 260°C, like standard PPR pipes. However, installers must ensure full EVOH layer continuity at joints. Proper techniques prevent delamination and maintain oxygen-blocking efficiency.

Environmental and Health Benefits

The EVOH layer is non-toxic and recyclable, aligning with eco-friendly construction trends. Unlike metal pipes, PPR pipes don’t leach heavy metals, ensuring safer drinking water in dual-purpose systems.

Future Trends and Innovations

Manufacturers are developing self-monitoring green PPR pipes with embedded sensors. These detect oxygen leaks in real time, further enhancing system reliability. As sustainable building practices grow, demand for these pipes will rise.

Conclusion

Green PP-R pipes are critical for corrosion-free heating systems. Their unique construction and color-coding ensure optimal performance. By understanding their purpose, homeowners and installers can make informed choices for durable plumbing solutions.