With the continuous improvement of people’s living standards, people pay more and more attention to the selection of materials in decoration and construction. When choosing pipe fitting materials, you may encounter two choices of brass pipe fittings and PPR pipe fittings. So, what is the difference between brass fittings and PPR fittings? Which material pipe fittings is better? Brass Fittings VS PPR Fittings,Now let’s learn this together.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

The difference between brass fittings and PPR fittings

Brass pipe fittings are an alloy composed of copper and zinc with high strength, excellent plasticity and corrosion resistance. Brass pipe fittings are usually used in water supply and HVAC systems of high-end buildings, and their main features are: high operating temperature, high compressive strength, good anti-corrosion ability, and easy processing. The price of brass pipe fittings will be slightly higher than that of PPR pipe fittings.

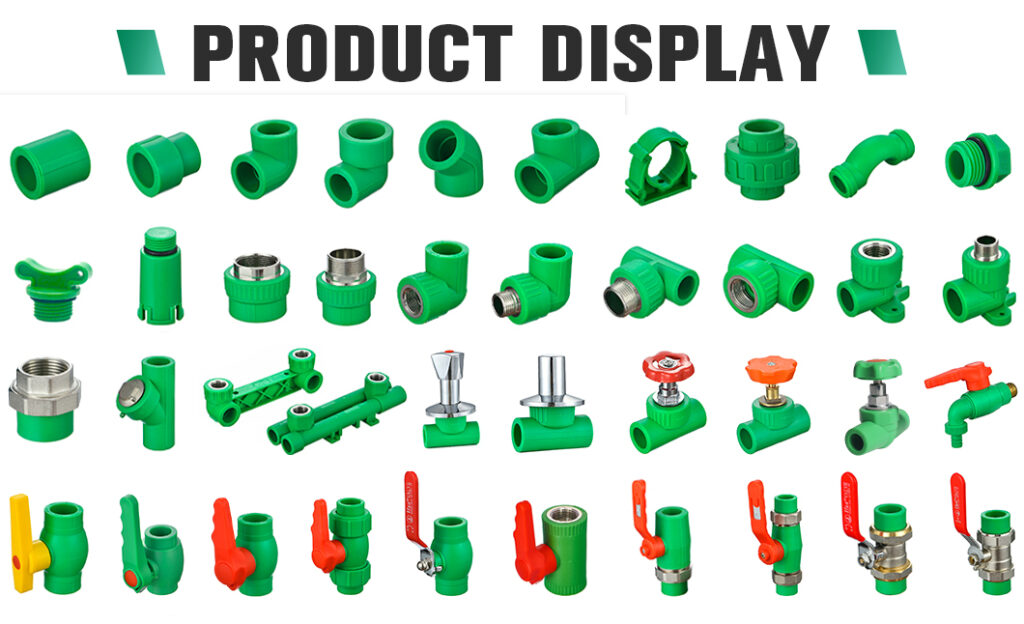

PPR pipe fittings are made of random polypropylene as the main raw material, and the piping system is produced through a special process. It has excellent physical and chemical properties, impact resistance, heat resistance, and sealing performance. It is suitable for hot and cold water pipes and chemical media. delivery. PPR pipe fittings are usually used in ordinary residences, public facilities and other fields. Its main features are: small thermal conductivity, light pipe body, not easy to age, and high cost performance. Moreover, the PP-R pipe does not contain halogen elements and will not release toxic substances, thereby ensuring the safety of water quality.

Advantages and Disadvantages of Brass Fittings and PPR Fittings.

Advantage:

- High strength and plasticity.

- It has good corrosion resistance, and its water quality will not be affected by factors such as pollution.

- It is easy to process, the heat treatment performance of the copper tube is relatively good, and the heat welding is convenient.

- The operating temperature is high and can withstand certain pressure.

Shortcoming:

- The cost is high.

- Installation requires experience, and the connection method of copper pipes needs to be mastered or professional personnel should be invited to install.

Advantage:

- The price is relatively low.

- Good sealing, no leakage.

- High corrosion resistance.

- There is no problem of radioactive pollution.

Shortcoming:

- The strength is low, and it is easy to be damaged by external force if you don’t pay attention.

- Large thermal expansion coefficient. Improper installation or poor operation may cause thermal expansion and rupture of the pipe.

Connection method

Connection method of brass pipe fittings

Copper tube connections include copper pressure tubes, welding, etc., but the more common way is to use brass tube compression connections. The compression connection method uses the metal rings in the compression sleeve to compress the compression sleeves at both ends of the pipe to achieve the purpose of sealing and sewing, but this connection method requires professionals to install, otherwise it is prone to water leakage.

The connection method of PPR pipe fittings

PPR pipe fittings have hot-melt connections and mechanical connections. The hot-melt connection strength is high, and the mechanical connection is easy to operate, but the connection strength is low. Care should be taken when connecting, and the mouth of the pipe must be free from scratches, oil and moisture, otherwise it will affect the sealing performance of the joint.

How to choose

When choosing pipe fitting materials, you must first choose the appropriate material according to your own needs. If it is used for daily water use at home and does not require ultra-high strength and pressure bearing capacity, then it is most appropriate to choose PPR pipe fittings. Especially for families with water quality requirements, PPR pipe fittings have more advantages, because PPR pipes will not affect the quality of water. If it is some high-end construction projects that require water pipes to have a higher pressure bearing capacity, then it is more appropriate to choose brass pipe fittings.

In short, brass pipe fittings and PPR pipe fittings have their own advantages and disadvantages. When purchasing pipe fittings, you need to consider various factors such as the bearing pressure of the project, price, water quality, and your own needs, and make a comprehensive evaluation and then make a selection. At the same time, during the installation process, the operation method of the pipe fittings should be followed to ensure safety and reliability, and at the same time, appropriate pipe fitting materials should be used according to the actual situation.