Unveiling the World of HDPE Pipe Manufacturers: Key Insights and Considerations

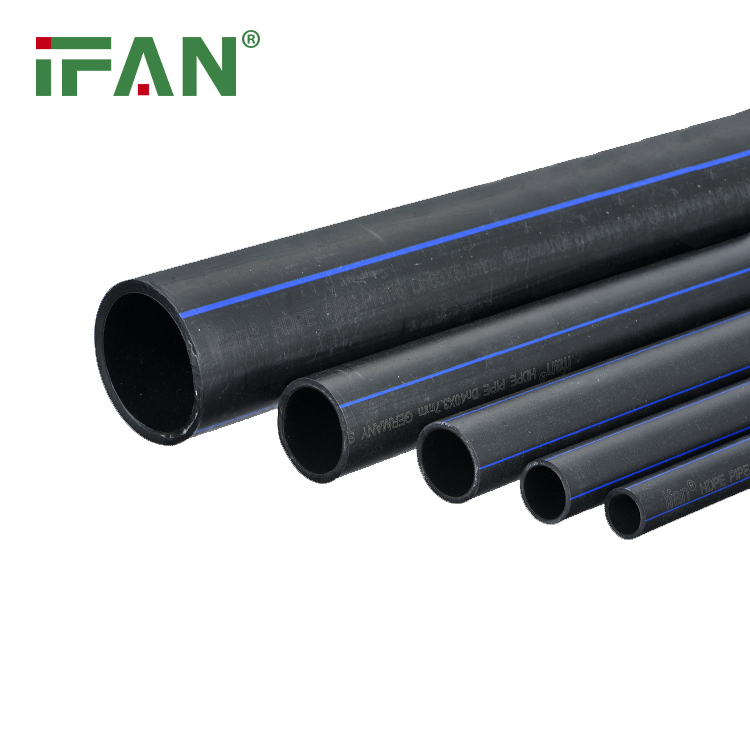

In the vast realm of infrastructure and construction, HDPE (High-Density Polyethylene) pipes play a vital role. These pipes, celebrated for their versatile applications and durability, have witnessed a surge in demand across various industries. When it comes to sourcing HDPE pipes, choosing the right manufacturer is paramount. In this extensive article, we embark on a journey through the world of HDPE pipe manufacturers, uncovering industry insights, critical considerations, and factors to guide you in making an informed decision.IFAN factory with 30+ years of manufacturing experience supports color/size customization and free samples. Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

I. The Significance of HDPE Pipe Manufacturers

HDPE pipes, manufactured by HDPE pipe manufacturers, are crucial elements in modern infrastructure projects. Their widespread usage can be attributed to several key features:

- Durability: HDPE pipes are renowned for their resilience in diverse environmental conditions, ensuring long-term reliability.

- Lightweight: The lightweight nature of HDPE pipes simplifies transportation, handling, and installation, leading to cost savings.

- Corrosion Resistance: HDPE pipes are immune to corrosion, making them suitable for water and wastewater applications.

- Flexibility: Their flexibility allows for easy adaptation to various terrains and installation conditions, reducing the need for additional fittings and joints.

II. Selecting the Right HDPE Pipe Manufacturer

Choosing the right HDPE pipe manufacturer is the cornerstone of securing high-quality materials for your projects. Several factors should influence your decision:

- Reputation and Experience: Opt for HDPE pipe manufacturers with a reputable history and a track record of delivering top-notch products.

- Certification and Compliance: Ensure that the manufacturer’s HDPE pipes meet industry standards and regulations, often indicated by relevant certifications.

- Product Range and Customization: Evaluate the variety of HDPE pipe products offered, as well as the manufacturer’s ability to provide customized solutions to meet specific project requirements.

- Availability and Lead Times: Timely delivery is essential for project efficiency; reliable manufacturers typically maintain adequate stock or offer short lead times.

- Customer Support: Excellent customer support, including prompt responses to inquiries, technical assistance, and after-sales support, can significantly simplify the procurement process.

III. Applications Across Industries

HDPE pipes manufactured by HDPE pipe manufacturers are versatile and find applications in various sectors:

- Water Distribution

- HDPE pipes are a staple in water distribution systems, both for potable water and irrigation purposes. Their corrosion resistance and long service life make them cost-effective for municipalities and water utilities.

- Gas Transmission

- Natural gas distribution demands pipes that can endure different environmental conditions. HDPE pipes are favored for their durability, low maintenance, and reliability in gas transmission networks.

- Mining

- The mining industry relies on HDPE pipes for slurry and tailings transport due to their remarkable abrasion resistance. These pipes help reduce maintenance and replacement costs, making them an ideal choice for mining applications.

- Agricultural Irrigation

- Agricultural irrigation systems use HDPE pipes to deliver water efficiently and sustainably. The pipes’ flexibility and corrosion resistance make them ideal for agricultural irrigation projects.

IV. Regional Insights on HDPE Pipe Manufacturers

The prominence and availability of HDPE pipe manufacturers can vary by region. Understanding the regional landscape is crucial for making informed decisions.

- North America

- North America boasts a thriving market of HDPE pipe manufacturers, given the extensive utilization of these pipes in water distribution, gas transmission, and industrial applications. Both local and international manufacturers cater to the region’s high demand.

- Europe

- Europe has seen an upsurge in the adoption of HDPE pipes in recent years, primarily in water and wastewater applications. Local manufacturers often provide products that adhere to European standards and regulations.

- Asia-Pacific

- The Asia-Pacific region has experienced significant growth in the use of HDPE pipes in construction, infrastructure, and agriculture. A mix of local and international manufacturers serves the burgeoning demand in this region.

- Middle East and Africa

- Owing to harsh environmental conditions, HDPE pipes are widely utilized in the Middle East and Africa, particularly for water distribution and mining applications. Many manufacturers in this region specialize in products suited to arid and challenging environments.

V. Diverse Types and Varieties of HDPE Pipes

HDPE pipes come in various types and varieties, each designed to cater to specific industry requirements. Understanding the different types of HDPE pipes can facilitate the selection of the most suitable option for your project. Some common types include:

- PE 80 and PE 100: Classification based on strength and pressure rating, where PE 100 pipes are suitable for higher-pressure applications, and PE 80 pipes are typically used for lower-pressure applications.

- SDR (Standard Dimension Ratio): A ratio representing the outside diameter of the pipe to its wall thickness, which determines the pipe’s suitability for specific pressure applications.

- Coil and Straight Length: Available in both coil and straight length formats, with coiled pipes being convenient for installations that require bending and flexibility, while straight lengths are used for more rigid applications.

- Fusion Jointing Methods: HDPE pipes are joined using various fusion methods, including butt fusion, electrofusion, and socket fusion, depending on the application and project requirements.

VI. Environmental Considerations

- Sustainability

- HDPE pipes are often considered an eco-friendly choice due to their recyclability. Many HDPE pipe manufacturers actively promote recycling programs, reducing the environmental impact of HDPE pipes.

- Leakage Reduction

- The seamless construction of HDPE pipes results in minimal leakage rates, conserving resources and minimizing the risk of contamination and water loss.

- Energy Efficiency

- The lightweight nature of HDPE pipes reduces transportation costs and energy consumption. Smaller equipment and fewer transport vehicles are needed for installation, resulting in reduced carbon emissions.

- Longevity

- The long service life of HDPE pipes means they require fewer replacements over time, reducing the overall environmental footprint of infrastructure projects.

VII. Quality Assurance and Testing for HDPE Pipes

To ensure the quality and reliability of HDPE pipes, HDPE pipe manufacturers perform thorough testing and quality assurance measures:

- Hydrostatic Testing: This test subjects the pipes to internal pressure to assess their ability to withstand the rated pressure without leaking or bursting.

- Tensile Testing: Tensile testing evaluates the pipes’ ability to withstand axial stress and elongation, an important factor in determining their durability.

- Impact Testing: This test assesses the resistance of HDPE pipes to impact or sudden shock, ensuring they can withstand external forces without cracking or breaking.

- Melt Flow Rate (MFR): Melt flow rate measures the flowability of the HDPE material, an essential test for understanding its processability and quality.

- Quality Control Documentation: Manufacturers should provide comprehensive quality control documentation, including test reports, certificates, and compliance statements, to ensure transparency and accountability.

VIII. Choosing the Right HDPE Pipe for Your Project

Selecting the appropriate HDPE pipe for your project is contingent on multiple factors, such as:

- Project Requirements: Understand the specific needs of your project, including pressure rating, size, and application, to select the most suitable HDPE pipe type.

- Environmental Conditions: Consider the environmental conditions to which the pipes will be exposed, such as temperature fluctuations, soil types, and potential chemical exposure, as these can impact the choice of HDPE pipe.

- Supplier Reputation: Choose a reputable HDPE pipe manufacturer with a history of delivering quality products, supported by certifications, compliance with industry standards, and positive customer feedback.

- Customization Options: For projects with unique requirements, look for manufacturers who can provide customized solutions to meet your needs.

IX. Maintenance and Repair of HDPE Pipes

HDPE pipes are known for their low maintenance requirements, but periodic inspections and maintenance activities can extend their service life. Maintenance tasks may include:

- Visual Inspections: Regular visual inspections can identify visible issues like scratches, cracks, or surface damage, allowing for prompt repairs to prevent further damage.

- Leak Detection: While HDPE pipes have low leakage rates, periodic checks for signs of leaks or seepage are essential to ensure timely repairs and prevent further damage.

- Cleaning: Cleaning the internal surfaces of HDPE pipes helps maintain flow efficiency, with the frequency depending on the transported material.

- Repairs: In the event of damage or wear, HDPE pipes can often be repaired using fusion techniques. Proper repair methods are essential to maintain the pipes’ structural integrity.

X. Future Trends in HDPE Pipe Manufacturing

The HDPE pipe manufacturing industry continues to evolve with advancements in technology and materials. Emerging trends and innovations to watch for include:

- Enhanced Resins: Manufacturers are developing new HDPE resins with improved characteristics, such as higher strength, enhanced resistance to chemicals, and greater flexibility.

- Smart Pipe Technology: Integration of sensors and monitoring systems to detect leaks, assess pipe conditions, and optimize maintenance schedules, enhancing efficiency and reliability.

- Sustainability Initiatives: The industry’s growing focus on sustainability, with manufacturers and end-users actively participating in recycling programs and promoting the circular economy for HDPE pipes.

- Larger Diameter Pipes: The demand for larger diameter HDPE pipes is on the rise, particularly in water transmission and infrastructure projects, leading manufacturers to scale up to meet these requirements.

Conclusion

HDPE pipes, manufactured by dedicated HDPE pipe manufacturers, are a linchpin in numerous industries, characterized by their durability, corrosion resistance, and flexibility. Selecting the right HDPE pipe manufacturer is pivotal for the success of your project. By understanding the applications, types, and environmental benefits of HDPE pipes, you can make informed decisions that cater to your project’s specific needs. Not only are HDPE pipes durable and reliable, but they also contribute to sustainability and environmental protection. As technology advances, the HDPE pipe manufacturing industry will continue to evolve, offering even more innovative solutions for diverse applications. Make sure to consider the reputation, certifications, and customization options when selecting an HDPE pipe manufacturer to embark on a successful journey in the world of infrastructure and construction.

IFAN

IFAN factory started in 1993. And IFAN has a workshop of 120000 square meters with 610 staff. IFAN can design and produce all plumbing pipe and fitting including PPR, PVC, CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting, brass fitting, brass ball valve, heating system, gas system, sanitary faucets, and hose, In the past 30 years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory uses the best materials to produce high-quality pipe and fittings with an automatic production line and high-tech quality control machines.