Introduction

PPR pipes and fittings are modern plumbing systems made of a unique form of thermoplastic polymer known as Polypropylene Random Copolymer. These pipes and fittings are widely used in both residential and commercial plumbing applications. They have gained popularity due to their excellent mechanical, chemical, and thermal properties, as well as their ease of installation and cost-effectiveness. In this article, we will discuss the structure, material, purpose, place of use, and installation procedures of PPR pipes and fittings. This is our Facebook Website:www.facebook.com.

Structure

PPR pipes and fittings are made up of Polypropylene Random Copolymer, which is a type of thermoplastic polymer. The pipes have a multi-layered structure that consists of an inner layer, a middle layer, and an outer layer. The inner layer is made of a thin layer of Polypropylene Random Copolymer, which ensures smooth water flow and prevents clogging. The middle layer is made of a thick layer of Polypropylene Random Copolymer, which provides the pipes with excellent mechanical strength and prevents deformation. The outer layer is made of a thin layer of Polypropylene Random Copolymer, which protects the pipes from ultraviolet radiation and other environmental factors.

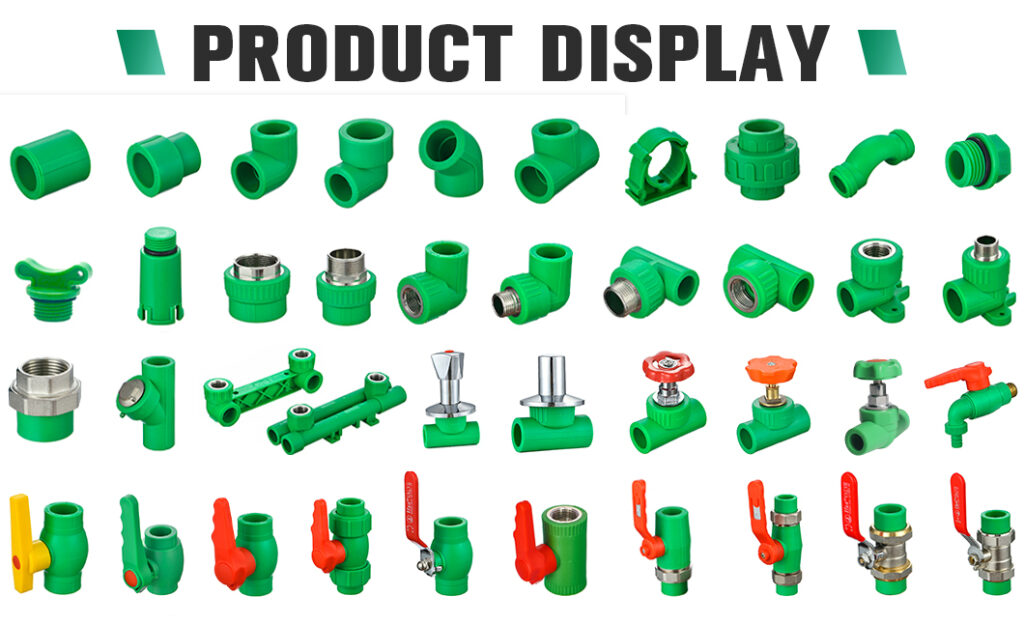

PPR fittings, on the other hand, come in various shapes and sizes, including elbows, tees, couplings, reducers, and end caps. These fittings are designed to connect PPR pipes to form a complete plumbing system. They are made of the same Polypropylene Random Copolymer material as the pipes, which makes them strong and durable.

Material

PPR pipes and fittings are made of Polypropylene Random Copolymer, which is a type of thermoplastic polymer. This material is known for its excellent mechanical, chemical, and thermal properties, making it suitable for plumbing applications. PPR pipes and fittings are non-toxic, odorless, and hygienic, making them ideal for use in drinking water systems. They are also resistant to high temperatures and pressure, making them suitable for hot and cold water distribution systems.

Purpose

The purpose of PPR pipes and fittings is to provide a reliable and cost-effective plumbing solution for both residential and commercial buildings. They are designed to provide smooth water flow and prevent clogging, which is crucial for maintaining a clean and healthy water supply. PPR pipes and fittings are also designed to withstand high temperatures and pressure, making them suitable for use in hot and cold water distribution systems.

Place of use for PPR pipes and fittings

PPR pipes and fittings are suitable for use in a wide range of applications, including residential and commercial buildings, hospitals, schools, and industrial facilities. They are ideal for use in hot and cold water distribution systems, as well as in heating and cooling systems. PPR pipes and fittings are also suitable for use in chemical and industrial applications due to their chemical resistance.

Installation

PPR (polypropylene random copolymer) pipe and fittings are commonly used in plumbing and heating systems. Here are the steps for installing PPR pipe and fittings. If you want to know more about our products, please feel free to contact IFAN, and we will provide you with the best choice!

1. Planning and preparation

Determine the system layout and design.

Select the appropriate PPR pipe and fittings for the project.

Gather the necessary tools and equipment.

2. Cutting and joining PPR pipes

Measure and cut the PPR pipes to the desired length.

Use a chamfering tool to remove any burrs or rough edges from the cut ends.

Apply PPR welding paste to the inside of the fitting and the outside of the pipe.

Use a welding machine to heat the fitting and pipe until the material melts and fuses together.

3. Installing PPR fittings

Install PPR fittings in the appropriate locations.

Connect the PPR pipes to the fittings using the same method described above.

4. Testing the system

Test the PPR system for leaks and proper operation.

Make any necessary adjustments or repairs.

Best Practices for Installing PPR Pipe and Fittings

To ensure a successful installation of PPR pipe and fittings, follow these best practices:

1.Use high-quality PPR materials from a reputable manufacturer.

2. Follow the manufacturer’s installation instructions carefully.

3. Use proper tools and equipment for cutting and joining PPR pipes and fittings.

4. Avoid damaging the PPR pipe and fittings during installation.

5. Test the system for leaks and proper operation before use.