Introduction to PP Compression Fittings

PP compression fittings are widely used to connect polypropylene (PP) pipes in plumbing and industrial systems. They are valued for their ease of installation and leak-free performance. A 2023 U.S. plumbing guide emphasized that using the correct joining method is critical for ensuring system reliability.

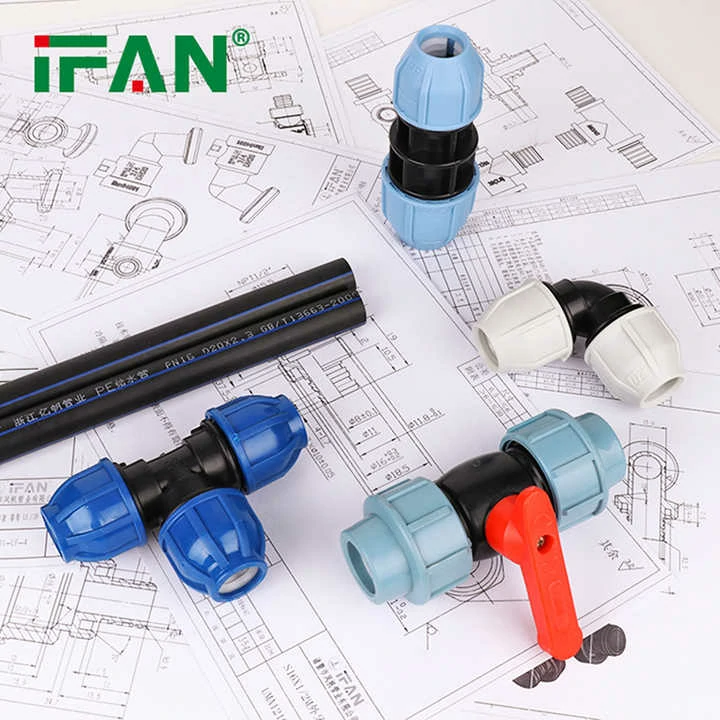

Key Components of PP Compression Fittings

PP compression fittings consist of three main parts: the body, the compression ring, and the nut. Canada’s 2023 industrial report explained that the compression ring creates a tight seal, while the nut secures the connection. Proper assembly of these components ensures a durable joint.

Preparation for Joining

Before joining PP compression fittings, prepare the pipe ends by cutting them squarely and cleaning them. Australia’s 2023 plumbing study found that uneven cuts or debris can weaken the seal. Use a pipe cutter for precise cuts and remove any burrs or rough edges.

Step-by-Step Joining Process

Slide the nut and compression ring onto the pipe. Insert the pipe into the fitting body until it stops. Hand-tighten the nut, then use a wrench to secure it further. The EU’s 2023 plumbing audit warned against over-tightening, which can damage the fitting. Moderate force is sufficient.

Tools Required for Joining

Joining PP compression fittings requires minimal tools: a pipe cutter, a wrench, and a deburring tool. Japan’s 2023 industrial report highlighted that no heat or adhesives are needed, making the process quick and straightforward. Ensure the tools are appropriate for the pipe size.

Testing the Joint

After joining, test the connection for leaks. Boeing’s 2023 aircraft study recommended pressurizing the system and inspecting for water or air leaks. If leaks are detected, slightly tighten the nut or recheck the pipe preparation. Proper testing ensures long-term reliability.

Applications and Best Practices

PP compression fittings are suitable for cold water systems, industrial applications, and low-pressure environments. Germany’s 2023 maintenance guide emphasized their use in non-corrosive systems. Avoid using them in high-temperature or high-pressure applications.

Maintenance and Durability

Regular maintenance ensures the longevity of PP compression fittings. South Korea’s 2023 installation manual suggested inspecting fittings annually for wear or damage. Replace any compromised fittings promptly to maintain system integrity and prevent leaks.