PPR Piping: An In-Depth Exploration for Various Industry Applications.Polypropylene Random Copolymer (PPR) piping is a versatile and efficient solution that has found extensive applications across various industries. In this comprehensive guide, we will delve into the world of PPR piping, understanding its composition, key characteristics, and how it is applied in different sectors.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our FacebookWebsite: www.facebook.com.

Introduction to PPR Piping

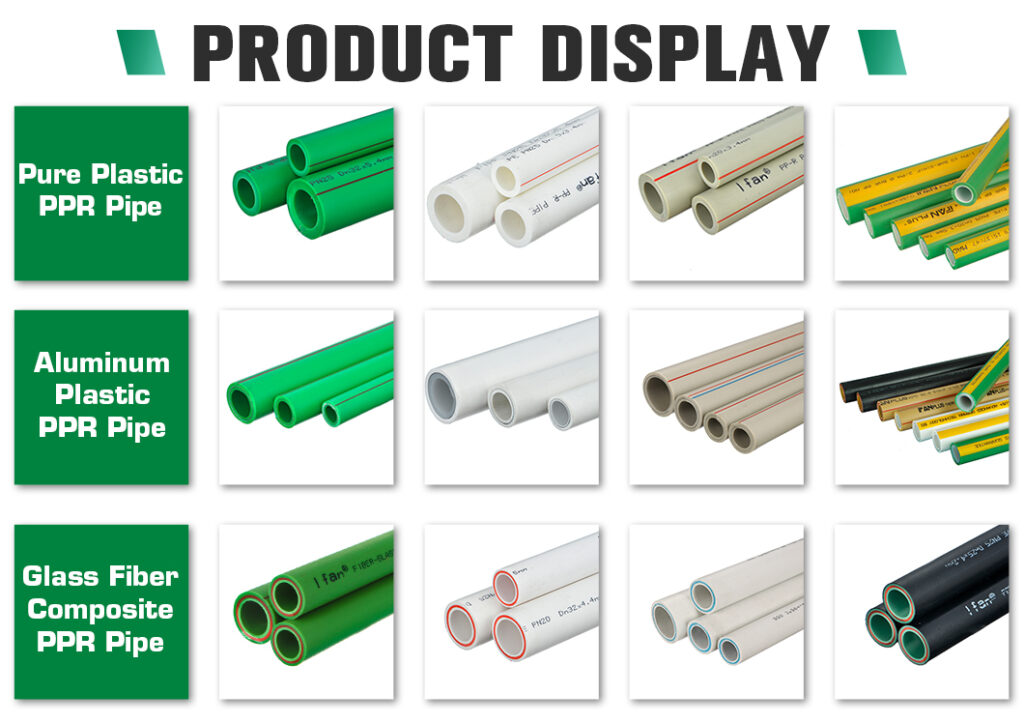

PPR, which stands for Polypropylene Random Copolymer, is a type of plastic piping known for its exceptional thermoplastic properties. It is widely used in the construction, industrial, and agricultural sectors for its suitability in transporting a variety of fluids. PPR pipes are manufactured from a copolymer of propylene and ethylene, making them an excellent choice for conveying both hot and cold liquids.

Key Characteristics of PPR Piping

PPR piping possesses a set of characteristics that render it a preferred choice in various applications:

1. Corrosion Resistance

One of the most significant advantages of PPR piping is its resistance to corrosion. Whether conveying aggressive chemicals, potable water, or industrial effluents, PPR pipes remain unaffected, ensuring the purity of transported fluids.

2. High Thermal Stability

PPR piping exhibits remarkable thermal stability, making it suitable for both hot and cold water systems. It can handle temperatures up to 90°C (194°F), which is well-suited for plumbing and heating applications.

3. Durability

PPR pipes are known for their robustness. They can withstand high pressure and are resistant to impact. This durability ensures longevity and minimizes maintenance requirements.

4. Low Thermal Conductivity

PPR’s low thermal conductivity minimizes heat loss, contributing to energy efficiency in heating systems.

5. Hygienic Properties

PPR pipes are considered safe for transporting potable water due to their non-toxic, lead-free, and corrosion-resistant nature.

Applications Across Industries

PPR piping finds its utility in various industry sectors:

1. Construction and Plumbing

In the construction sector, PPR pipes are widely used for water supply, heating, and sanitation systems. Their durability and hygienic properties make them ideal for plumbing applications in residential and commercial buildings.

2. Industrial Sector

PPR piping plays a crucial role in the industrial landscape. It is used for transporting chemicals, industrial fluids, and wastewater due to its resistance to corrosion and high-temperature stability.

3. Agriculture and Greenhouses

Agriculture and greenhouse operations require efficient irrigation systems. PPR pipes offer durability and resistance to chemical fertilizers and pesticides, making them suitable for agricultural water supply.

4. Swimming Pools and Spa Facilities

PPR piping is essential for swimming pool and spa facilities, ensuring the continuous and hygienic circulation of water.

5. Gas Transportation

PPR pipes are also used for gas distribution, particularly in regions where safety regulations and material standards permit their use.

6. Infrastructure and Municipal Projects

PPR piping is commonly used in municipal projects, including the construction of water treatment plants and sewerage systems.

7. Geothermal Applications

In geothermal heating and cooling systems, PPR pipes are favored for their ability to withstand high-temperature variations.

8. Food and Beverage Industry

The food and beverage industry uses PPR piping for fluid transportation due to its non-toxic, non-corrosive, and hygienic properties.

Maintenance and Care

To ensure the longevity and efficiency of PPR piping, regular maintenance is crucial. This includes periodic inspections for leaks, ensuring proper joint integrity, and addressing any signs of wear or damage.

Conclusion

PPR piping is a versatile, durable, and efficient solution that serves a multitude of purposes across different industries. Its unique properties, including corrosion resistance, high thermal stability, and non-toxic nature, make it an attractive choice for various applications. Understanding the advantages and applications of PPR piping is key to maximizing its potential in diverse sectors. Whether in construction, industry, agriculture, or municipal projects, PPR piping continues to provide reliable and sustainable solutions for fluid transport.