beok In the pursuit of sustainable and energy-efficient building practices, the choice of piping systems plays a crucial role. The Polypropylene Random Copolymer (PPR) piping system has gained prominence, not only for its durability but also for its potential in minimizing energy consumption. This article delves into the energy-saving aspects of PPR piping systems, focusing on the intricate relationship between heat loss and fittings.

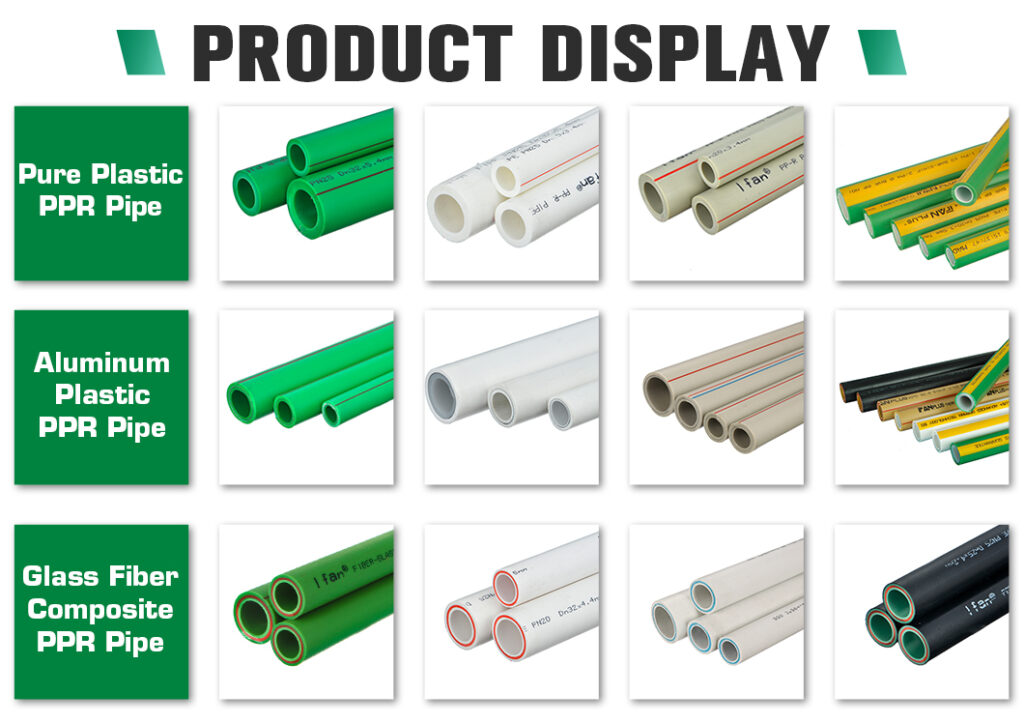

IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

The Thermal Dynamics of PPR Piping Systems

Understanding the thermal dynamics of a piping system is fundamental to addressing energy efficiency concerns. PPR, being a thermoplastic material, exhibits low thermal conductivity, which is advantageous in reducing heat transfer across the system.

The Role of PPR Piping Systems Fittings in Heat Loss

Fittings, although essential for directing and controlling the flow of fluids, can be potential points of heat loss in a piping system. Traditional materials and inefficient jointing methods may contribute to increased heat dissipation, leading to energy wastage.

Advantages of PPR Piping Systems in Mitigating Heat Loss

1. Low Thermal Conductivity

PPR fittings, owing to their low thermal conductivity, act as effective insulators. This property minimizes heat transfer at connection points, reducing overall heat loss in the system.

2. Homogeneous Fusion Joints

PPR fusion technology ensures that fittings create homogeneous joints with the pipes. This seamless integration eliminates gaps or weak points, preventing heat from escaping at connection sites.

3. Reduced Thermal Bridges

Traditional metallic fittings can act as thermal bridges, facilitating heat transfer. PPR fittings, being thermoplastic, disrupt these thermal bridges, offering a more energy-efficient solution.

Applications of PPR Piping Systems in Heating Systems

The relationship between heat loss and fittings becomes particularly crucial in heating systems. PPR’s ability to mitigate heat loss ensures that the energy invested in heating the fluid is effectively utilized, contributing to enhanced system efficiency.

Achieving Optimal Energy Efficiency

1. Proper Insulation

While PPR inherently reduces heat loss, supplementing the system with proper insulation further enhances energy efficiency. Insulating critical points, including fittings, helps maintain the desired temperature within the pipes.

2. Regular Maintenance

Periodic checks and maintenance of fittings ensure that the system remains free from leaks or degradation that could contribute to increased heat loss over time.

Conclusion

The energy-saving potential of PPR piping systems lies not only in the inherent properties of the material but also in the design and quality of fittings. By understanding the relationship between heat loss and fittings, stakeholders in construction and plumbing can make informed decisions to create sustainable and efficient piping systems. PPR’s contribution to minimizing energy wastage underscores its position as a key player in the evolution of environmentally conscious building practices.