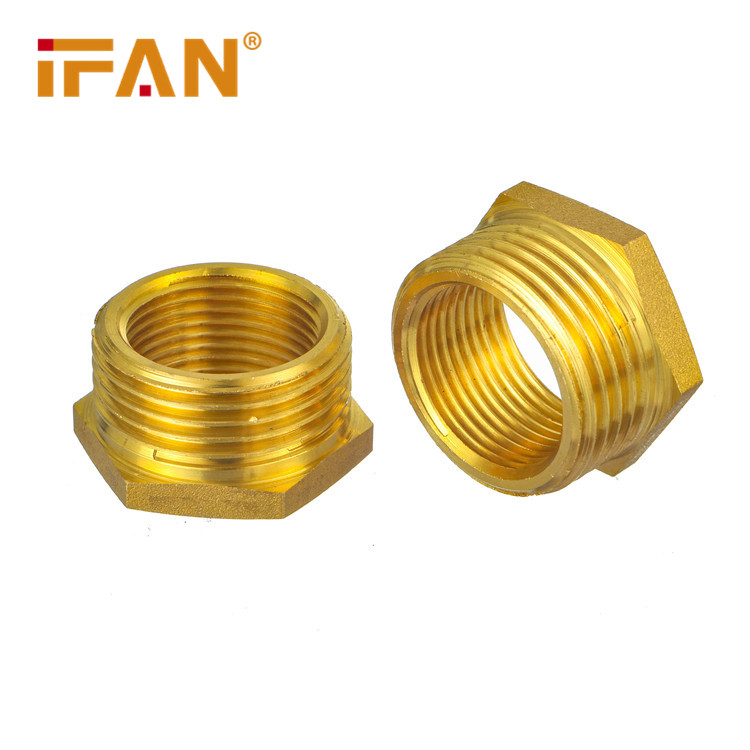

Brass Bushing

Brand Name: IFAN

Product Name: Brass Bushing

Color: Brass Color

Size: 1/2”-2”

Pressure: PN25

Sample: Free Sample

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

Brass Bushing: Everything You Need to Know

Have you ever heard of a brass bushing? If you haven’t, you might not know how important these small-but-mighty components are to many machines and equipment. A brass bushing is a type of bearing that provides a low-friction surface for rotating parts, reducing wear and increasing the lifespan of the equipment. In this article, we will cover everything you need to know about brass bushings, including their uses, benefits, and maintenance.IFAN factory has 30+ years of manufacturing experience supporting color/size customization support free samples.Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com

What is a Brass Bushing?

A brass bushing is a type of bearing, which is a machine element that reduces friction between moving parts. It consists of a cylindrical metal sleeve or tube that fits around a rotating shaft, providing a low-friction surface for the shaft to rotate on. The space between the shaft and the sleeve is filled with lubricant, which reduces friction and wear on both parts.

Uses of Brass Bushings

Brass bushings are used in many types of equipment, from cars and trucks to industrial machinery and household appliances. They are commonly found in hydraulic systems, engines, transmissions, and suspension components. Brass bushings are also used in electrical motors, pumps, and water treatment systems.

Benefits of Brass Bushings

One of the main benefits of brass bushings is their ability to reduce friction and wear on moving parts. This increases the lifespan of the equipment and reduces the need for maintenance and repairs. Brass bushings are also relatively inexpensive and easy to replace, making them a cost-effective solution for many applications.

Another benefit of brass bushings is their resistance to corrosion and rust. Brass is a corrosion-resistant material, which means it can withstand exposure to moisture, chemicals, and other environmental factors. This makes brass bushings ideal for use in harsh environments where other materials may fail.

Maintenance of Brass Bushings

Like any other component, brass bushings require maintenance to ensure optimal performance and longevity. Regular lubrication is essential to prevent friction and wear on the parts. The lubricant should be applied according to the manufacturer’s recommendations, and the bushings should be inspected regularly to ensure they are still in good condition.

If a brass bushing is damaged or worn beyond repair, it should be replaced with a new one. A damaged bushing can cause vibration, noise, and other issues that can affect the performance and safety of the equipment. It is important to replace worn or damaged bushings as soon as possible to prevent further damage to the surrounding parts.

Conclusion

In summary, brass bushings are an essential component in many types of equipment and machinery. They provide a low-friction surface for rotating parts, reducing wear and increasing the lifespan of the equipment. Brass bushings are relatively inexpensive, easy to replace, and resistant to corrosion and rust. Regular maintenance is essential to ensure optimal performance and prevent damage to the surrounding parts. If you’re looking for a reliable, cost-effective solution for your machinery or equipment needs, brass bushings are a great choice.

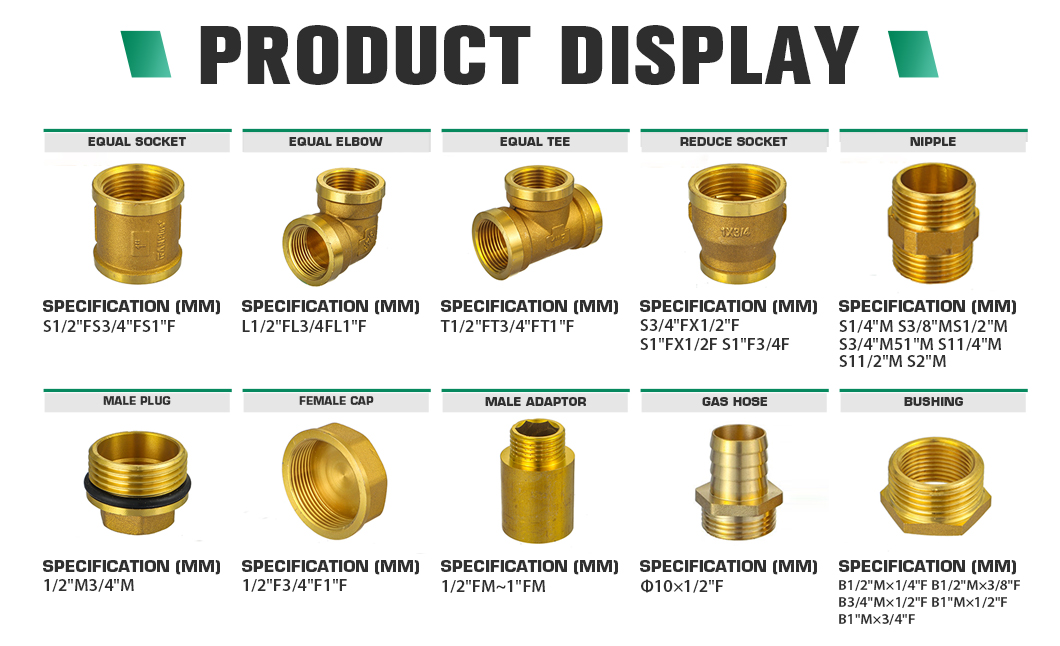

相关产品

-

Brass Fittings

Brass Equal Elbow

-

Brass Fittings

Brass Female Tee

-

Brass Fittings

Brass Reduce Nipple

-

Brass Fittings

Brass Fittings Elbow

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US