Description

Brass Fittings Nipples are essential components widely used in plumbing, hydraulic systems, HVAC (heating, ventilation, and air conditioning), and various industrial applications. These fittings and nipples are designed to connect pipes or tubing, facilitating the flow of liquids or gases through a system. They come in various shapes, sizes, and configurations, and are typically used to join pipes of different diameters or to change the direction of flow.

Materials

Brass is an alloy primarily composed of copper and zinc, with varying proportions of other metals like lead, tin, and iron. The specific material grade used for brass fittings can impact performance characteristics such as strength, corrosion resistance, and machinability.

- Copper-Zinc Alloys (Yellow Brass): The most common type of brass, with a zinc content of around 30-40%. This alloy is widely used for plumbing fittings due to its excellent corrosion resistance and machinability.

- Leaded Brass: Brass containing lead (usually around 2-4%) for improved machinability. It is often used in applications where complex machining is required, though it is becoming less common in drinking water systems due to health concerns.

- Red Brass (Bronze): With a higher copper content (up to 90%), red brass provides better resistance to corrosion, making it suitable for high-performance and specialized applications.

- High-Strength Brass: Some brass alloys include additional elements like iron or manganese for higher strength and wear resistance, which is crucial in heavy-duty industrial applications.

Manufacturing Process

The production of brass fittings and nipples typically involves the following steps:

- Casting or Forging: Brass ingots are either cast into molds or forged into blanks. This step determines the basic shape of the fitting or nipple.

- Machining: The rough castings are then machined to the final dimensions, using CNC (computer numerical control) machines, turning, and milling processes. Threads are often cut onto the fittings for easy connection to pipes.

- Finishing and Plating: After machining, the fittings may undergo surface treatments such as polishing, coating, or plating (e.g., nickel or chrome plating) to enhance their appearance and corrosion resistance.

- Quality Control: Finished products undergo rigorous testing for dimensional accuracy, pressure resistance, and overall quality. These fittings may also be subject to pressure testing, corrosion resistance tests, and leakage assessments.

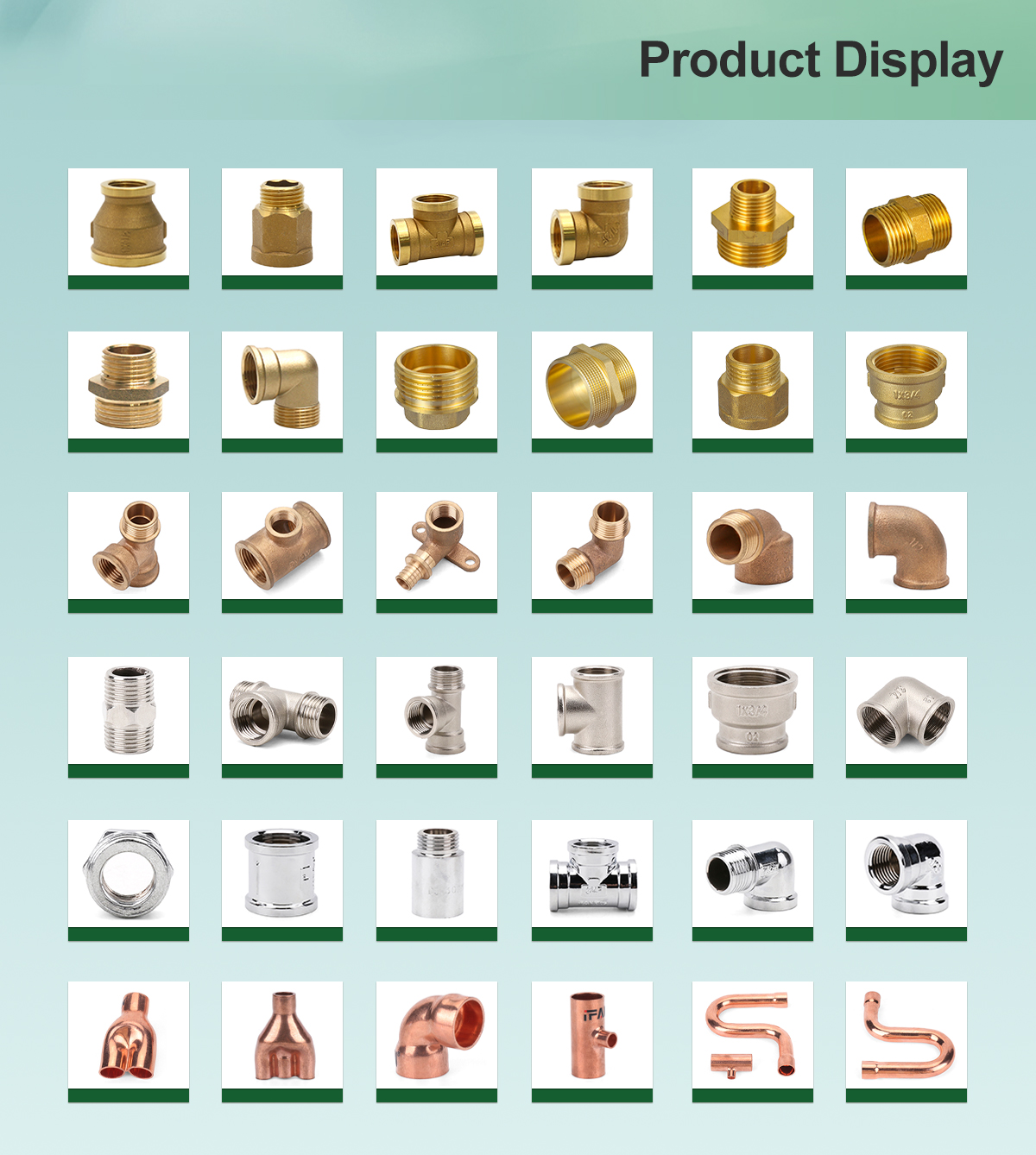

Types

- Straight Nipples: These are the most basic type of nipple, consisting of a single straight piece with threaded ends to connect two pipes of the same diameter.

- Reducing Nipples: These nipples have different sizes on each end, allowing the connection of pipes of different diameters. They are commonly used in applications where a change in pipe size is required.

- Elbow Fittings: Brass elbows are used to change the direction of pipework, commonly available in 90-degree, 45-degree, and other configurations.

- Tee Fittings: Brass tees are used to connect three pipes, allowing a branch to be formed from a main line.

- Couplings: These are used to connect two sections of pipe of the same size, often used to extend a pipe run.

- Union Fittings: A type of connector that allows easy disassembly of two connected pipes, used for maintenance or replacement.

- Adapter Fittings: These fittings allow for the connection of pipes with different thread types or sizes.

Advantages

- Corrosion Resistance: Brass exhibits excellent resistance to corrosion, making it ideal for use in plumbing systems, especially in water and gas lines. It resists rust and staining, maintaining the integrity of the system over time.

- Durability: Brass fittings are strong and durable, capable of withstanding high-pressure environments. They have a long lifespan, reducing the need for frequent replacements.

- Malleability and Workability: Brass is easy to machine and can be molded into complex shapes with ease. This makes it suitable for various applications requiring precise fit and custom configurations.

- Thermal and Electrical Conductivity: Brass offers good thermal conductivity, making it suitable for heating systems. It also provides electrical conductivity, which is beneficial in some specialized applications like grounding systems.

Key Characteristics

- Strength: Brass is strong enough to handle high-pressure systems without cracking or leaking.

- Resistance to High Temperatures: Brass can withstand high temperatures, making it suitable for hot water or steam applications.

- Ease of Installation: Brass fittings are easy to install with standard tools, saving time and labor costs in the field.

Conclusion

Brass fittings nipples remain a reliable and popular choice across multiple industries due to their combination of strength, corrosion resistance, and ease of manufacture. Their versatility makes them indispensable in plumbing, HVAC, and industrial fluid systems. Whether you’re dealing with potable water, gas, or high-pressure systems, brass fittings offer the durability and performance necessary to maintain long-term operational efficiency.

相关产品

- PVC Pipe & Fittings

IFAN CPVC Pipe

- PVC Pipe

IFAN PEX Equal Elbow

- PVC Pipe & Fittings

PVC CPVC Pipe

- PVC Pipe & Fittings

CPVC Pipe

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US