Description

Introduction to PPH Pipe Fittings

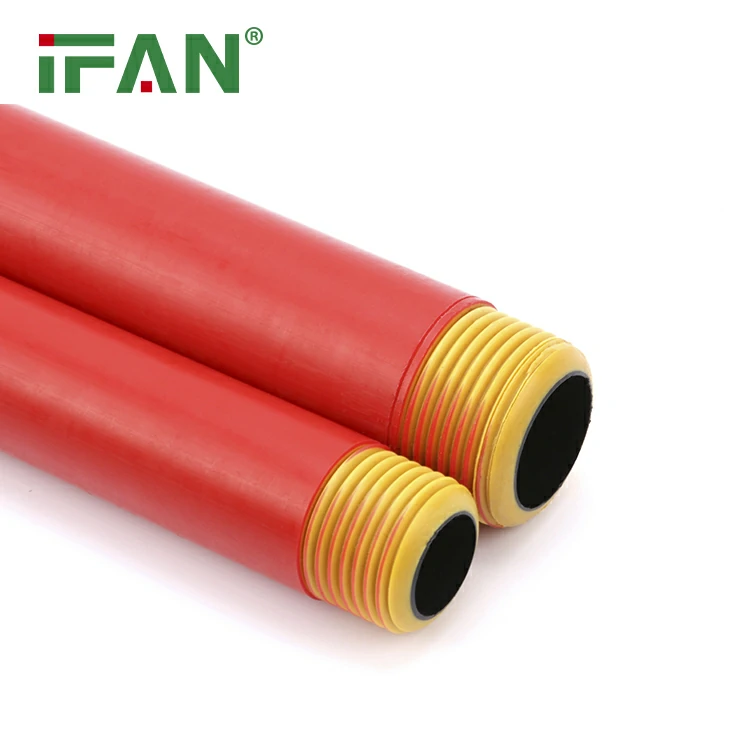

PPH pipe fittings are made from polypropylene homopolymer, known for excellent chemical and thermal resistance.

They are widely used in chemical processing, industrial plumbing, and water treatment applications.

These fittings ensure tight, secure, and corrosion-resistant connections.

Proper installation of PPH pipe fittings is essential for reliable system performance.

This article explains step-by-step how to connect PPH pipe fittings correctly and safely.

Understanding the Connection Methods

There are several ways to connect PPH pipe fittings: socket fusion, butt fusion, and mechanical joints.

Socket fusion is common for small-diameter pipes.

Butt fusion is used for larger pipes needing high-strength joints.

Mechanical connections use threaded or flanged fittings, useful for temporary or movable systems.

Choosing the right connection method depends on the application and system pressure.

Always follow manufacturer instructions for the best results.

Preparation Before Installation

Start by gathering the correct size of PPH pipe fittings and compatible tools.

Ensure all pipe ends are clean, dry, and free from grease or debris.

Measure and mark the insertion depth on each pipe end.

Use a pipe cutter to make clean, square cuts.

Deburr and chamfer the pipe edges to ensure smooth insertion.

Proper preparation helps avoid weak joints and leakages.

Socket Fusion Process

Socket fusion is ideal for PPH pipe fittings up to 110mm in diameter.

First, preheat the socket fusion tool to the recommended temperature (usually around 260°C).

Insert both the pipe and fitting into the heated sockets simultaneously.

Hold them in place for the specified heating time.

Quickly remove and join them, applying even pressure without twisting.

Hold steady until the joint cools completely.

This method creates a strong, homogenous joint.

Butt Fusion Welding Steps

Butt fusion is suitable for larger PPH pipe fittings above 110mm diameter.

Align the pipe and fitting in a butt fusion machine.

Use a facer to trim the ends squarely.

Heat the ends with a hot plate at the required temperature.

Once softened, remove the plate and press the ends together.

Maintain pressure until the joint cools and solidifies.

The result is a seamless, pressure-resistant joint.

Mechanical Joint Installation

For flexible or temporary connections, use mechanical joints for PPH pipe fittings.

Flanged ends and threaded couplings are typical options.

Ensure gaskets are clean and seated properly in flanged connections.

Tighten bolts evenly in a cross pattern to prevent leaks.

For threaded fittings, use Teflon tape or sealant on male threads.

Hand-tighten, then use a wrench for a snug fit—avoid over-tightening.

Pressure Testing and Inspection

After connecting PPH pipe fitting, pressure testing is essential before commissioning.

Fill the system with clean water or air.

Pressurize to the recommended test level for at least 30 minutes.

Inspect all joints for leaks, bulging, or movement.

Any failure indicates improper installation or material defects.

Correct all issues before placing the system into service.

Document the test results for quality assurance.

Conclusion and Best Practices

Connecting PPH pipe fitting requires careful preparation, proper technique, and attention to detail.

Choose the right joining method based on system size and pressure.

Use only certified tools and follow heating times strictly.

Avoid contamination during installation to ensure chemical resistance.

Regular training for technicians ensures consistent quality.

With correct installation, PPH pipe fitting provides long-term performance in demanding environments.

相关产品

- PPH Fittings

IFAN Plastic PPH Pipe Fittings

- PPH Fittings

IFAN ISO 15494 PPH Tank Connector

- PPH Fittings

IFAN DIN 8077/8078 PPH Union

- PPH Fittings

PPH Fittings

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US