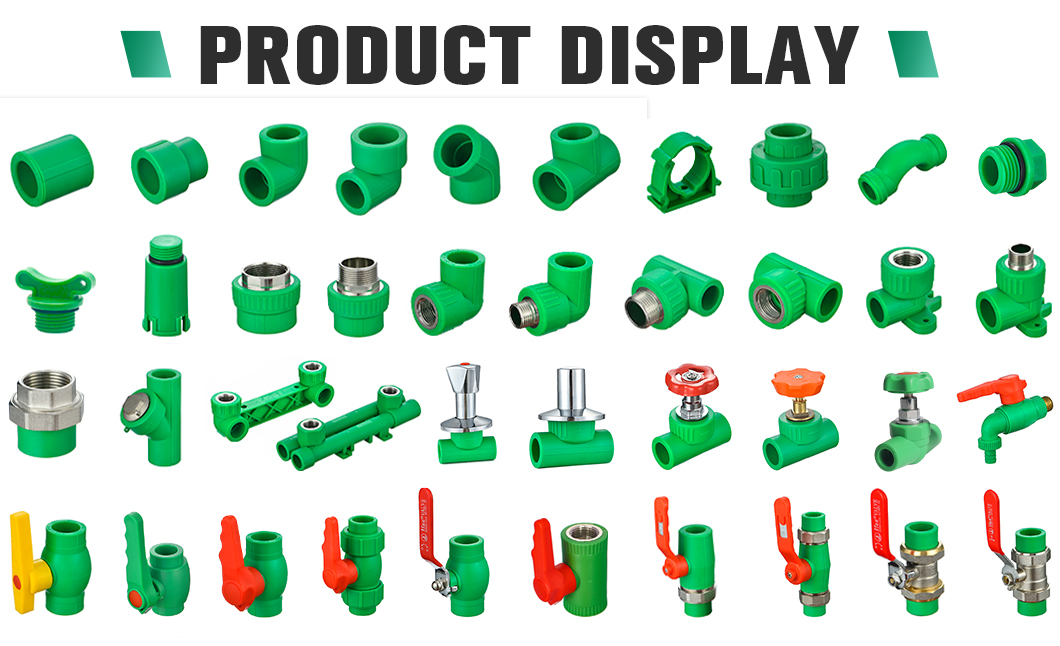

PPR Piping

Name:PPR Piping

Color: Green

Size:20-110mm

Sample: Free

Brand: IFAN

Service:OEM ODM

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

The Indispensable Role of PPR Piping Across Demanding Pipeline Environments

SAM-UK Pipelines transporting water, chemicals, oil, gas, and more face immense pressures, corrosion, vibrations, and temperature fluctuations. The right pipe material is crucial for resilience in these environments. PPR (polypropylene random) piping has emerged as an optimal solution due to its durability, chemical resistance, and leakproof properties.IFAN factory has 30+ years of manufacturing experience supporting color/size customization support free samples. Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

What is PPR Piping?

SAM-UK PPR refers to a random copolymer made from propylene and a small amount of ethylene. PPR piping consists of this rugged, flexible material capable of withstanding the most punishing pipeline demands.

Benefits of PPR Pipes & Fittings

Here are the key advantages of PPR piping systems:

- High Tensile Strength – Withstand pressures over 1.6 MPa without rupture.

- Temperature Resistance – Unaffected by temperatures from -15°C to 95°C.

- Corrosion Resistance – Inert to chemical attack from acids, alkalis, salts, and oils.

- Fatigue Resistance – Endures ongoing vibrations and pressure surges.

- Reliable Joints – Leakproof fusion joints even under strain.

- Lightweight – Significantly lighter than metal, allowing easy handling.

- Non-toxic – Suitable for potable water and food processing fluids.

- Easy Installation – Flexible pipes simplify routing and require fewer joints.

- Long Lifespan – Outlasts steel, copper, and iron piping.

Key PPR Piping Applications

PPR piping thrives across scenarios including:

- Transporting Chemicals – Acids, brine, solvents, alkalis.

- Hot Fluid Lines – Temperatures up to 95°C.

- Chilled Fluid Lines – Temperatures down to -15°C.

- Congested Areas – Tight space installation.

- Corrosive Environments – Resists salt, moisture, and a wide variety of chemicals.

- Underground Pipelines – withstand soil stresses and groundwater.

With the capacity to withstand the most punishing pipeline conditions, SAM-UK PPR piping has proven to be the top material choice for engineers. Its unparalleled durability, chemical resistance, and ease of use ensure safe and reliable fluid transport.

相关产品

-

PPR Fitting

white PPR 45°Elbow

-

PPR Fitting

White PPR Female Elbow Fittings

-

PPR Fitting

White PPR Elbow Fittings

-

PPR Fitting

PPR End Cap

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US