PPR plumbing material fitting

Name:PPR plumbing material fitting

Brand:IFAN

Category : Click Download

Whatsapp : +86 19884503412</p>

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

1. Material Composition

PPR DIN 8077/8078 (Polypropylene Random Copolymer) plumbing fittings are primarily made from high-quality PPR material. The main components include:

- PPR (Polypropylene Random Copolymer): A type of thermoplastic polymer that provides excellent chemical resistance, high impact strength, and a high melting point. PPR is non-toxic and resistant to high temperatures and pressure, making it an ideal material for plumbing systems.

- Reinforcing Additives: Some PPR fittings may include reinforcing agents to improve their performance under high-pressure conditions, especially in industrial and commercial applications.

These materials ensure that PPR plumbing material fitting are durable, safe, and efficient for a variety of applications.

Manufacturing Process

The production of PPR plumbing material fitting involves the following stages:

- Material Sourcing: High-quality polypropylene random copolymer is sourced, often along with reinforcing agents to ensure superior strength and durability.

- Extrusion: The raw PPR material is melted and extruded into pipe shapes, which will later be cut into specific lengths for fittings.

- Injection Molding: PPR fittings such as elbows, tees, couplings, and reducers are manufactured using injection molding techniques. This allows for precise shaping and the creation of complex geometries needed for various plumbing applications.

- Heat Fusion Welding

- Quality Control and Testing

Types

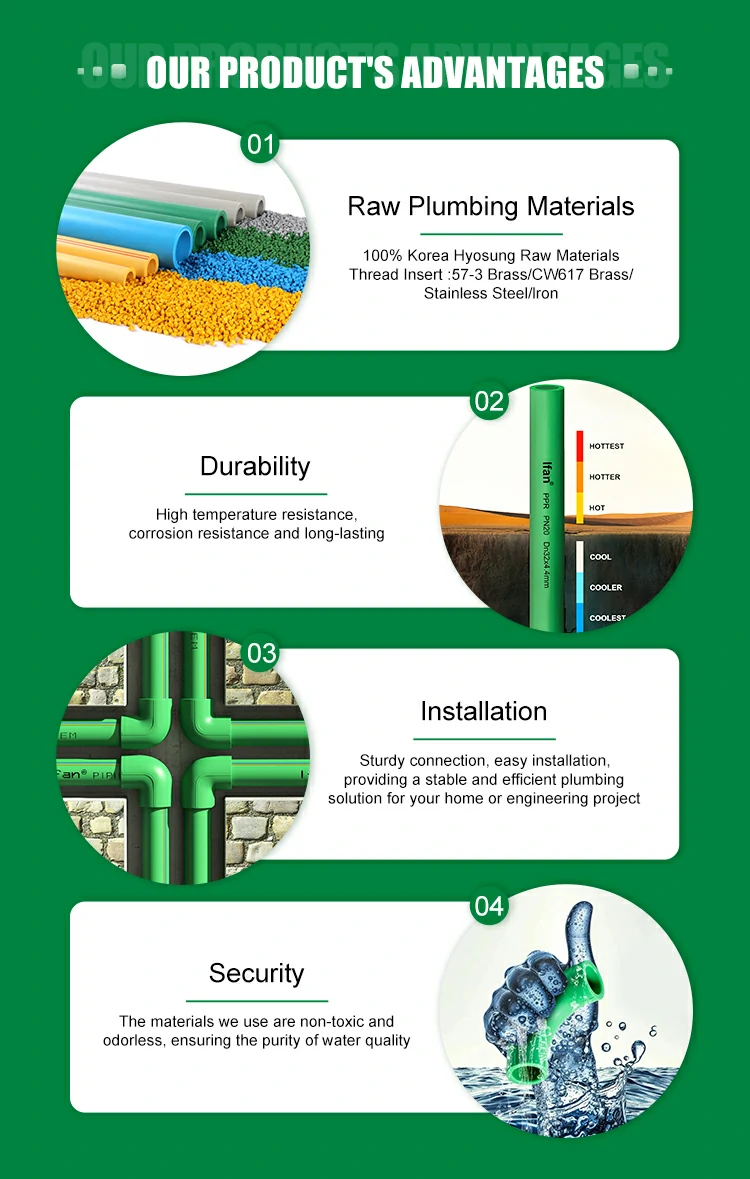

Advantages

PPR plumbing fittings offer several notable advantages:

- Durability: PPR fittings are highly durable, offering long-term reliability even in challenging conditions. They are resistant to corrosion, scale build-up, and UV degradation.

- High Temperature and Pressure Resistance: PPR material can withstand high temperatures (up to 95°C/203°F) and pressures, making it suitable for hot water systems, underfloor heating, and industrial applications.

- Non-Toxic and Safe: PPR is non-toxic and does not release harmful chemicals, making it safe for drinking water systems and other potable water applications.

- Ease of Installation: The heat fusion joining method is easy to perform, does not require glue or solvents, and provides a strong, leak-proof connection.

- Low Thermal Conductivity: PPR’s low thermal conductivity makes it ideal for hot water systems, reducing heat loss and improving energy efficiency.

- Cost-Effective: PPR fittings are affordable and offer a long service life, reducing the need for frequent repairs or replacements.

By utilizing PPR material, plumbing systems benefit from improved longevity, reduced maintenance costs, and better overall efficiency. PPR plumbing fittings continue to be a preferred choice in a wide range of applications due to their superior qualities and ease of installation.

相关产品

- PPR Fitting

White PPR Elbow With Seat

- PPR Fitting

PPR Male Elbow

- PPR Fitting

PPR Tee Fittings

- PPR Fitting

PPR Elbow Fittings

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US