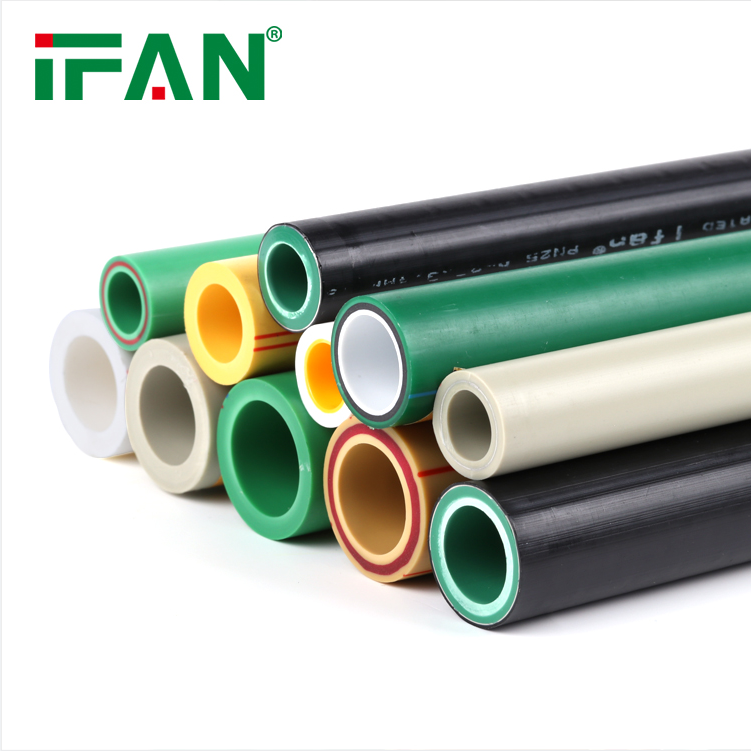

Various PPR Pipes

| Product Name: IFAN Various PPR Pipe Size: 20-160mm Pressure: PN25 Package: IFAN Woven Bag Sample: Free Sample Delivery: 15 Days |

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

Various PPR pipes are widely used in plumbing, heating, and cooling applications. They are strong, durable, and reliable and come in various sizes and shapes. In this article, we will look at the different types of PPR pipes available in the market and their features.

IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

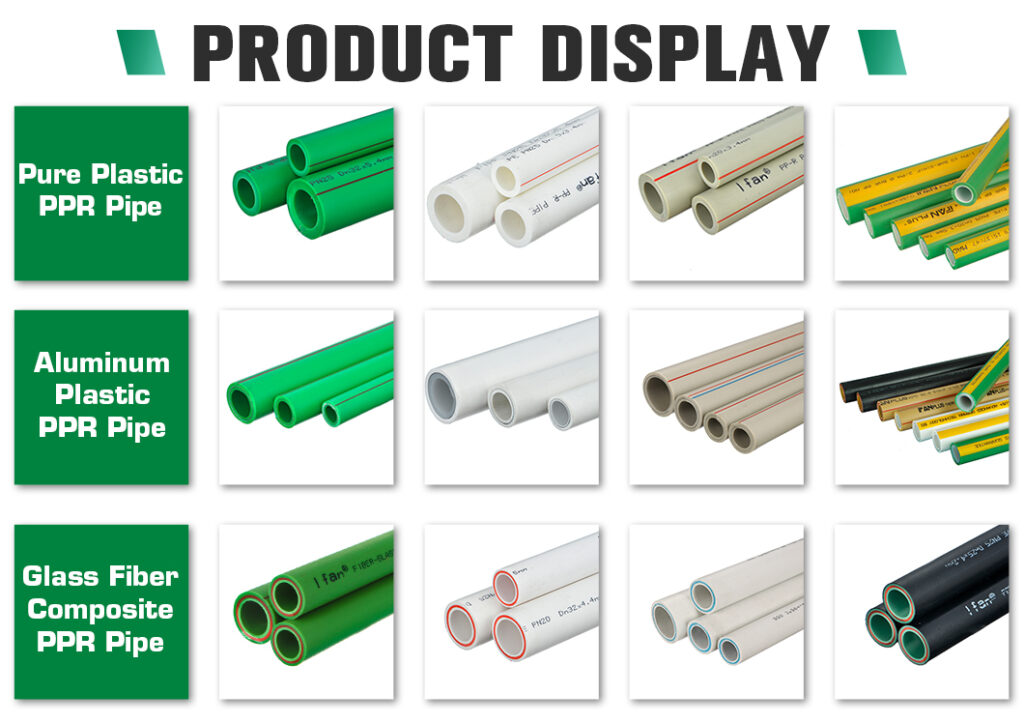

Types of Various PPR Pipes

1. PPR-Al-PPR pipes

PPR-Al-PPR pipes are made by sandwiching a layer of aluminum between two layers of PPR. This gives the pipes added strength and helps to prevent the build-up of bacteria and other microorganisms. The aluminum layer also helps to protect the pipes from UV radiation and makes them resistant to corrosion.

2. PPR-AL-PE pipes

PPR-AL-PE pipes are similar to PPR-Al-PPR pipes, but instead of aluminum, they have a layer of cross-linked polyethylene. This gives the pipes added flexibility and makes them easier to install in tight spaces. PPR-AL-PE pipes are also resistant to high temperatures and pressure.

3. PPR-FR-PPR pipes

PPR-FR-PPR pipes are made using a flame retardant material that makes them more resistant to fire. They are commonly used in buildings where fire safety is a concern. PPR-FR-PPR pipes are also resistant to chemicals and UV radiation and can withstand high temperatures and pressure.

4. PPR-C pipes

PPR-C pipes are made using a modified version of PPR that contains chlorine. This makes the pipes more resistant to high temperatures and pressure and increases their chemical resistance. PPR-C pipes are commonly used in industrial applications where harsh chemicals are present.

5. PPR-CT pipes

PPR-CT pipes are made using a new thermal-stabilized PPR compound that is resistant to creep and fatigue. This makes the pipes more durable and reliable, even under extreme conditions. PPR-CT pipes are also resistant to chemicals and UV radiation and can withstand high temperatures and pressure.

Advantages of Various PPR Pipes

1. Durability

PPR pipes are highly durable and can last for decades without any issues. They are resistant to corrosion, chemicals, and UV radiation and do not degrade over time.

2. Low maintenance

PPR pipes require very little maintenance and do not need to be replaced as often as other types of pipes. They are also easy to clean and do not accumulate debris or scale.

3. Cost-effective

PPR pipes are affordable and cost-effective to install and maintain. They also have a low friction coefficient, which helps to reduce energy consumption and save on costs.

4. Environmentally friendly

PPR pipes are made using non-toxic materials and are 100% recyclable. They do not emit any harmful chemicals or gases and have a low carbon footprint.

Conclusion

Various PPR pipes are a versatile, reliable, and cost-effective solution for plumbing, heating, and cooling applications. With a wide range of options available in the market, there is a PPR pipe to suit every requirement. Whether you are looking for durability, low maintenance, cost-effectiveness or environmental friendliness, PPR pipes are a great choice.

相关产品

- PPR Pipe

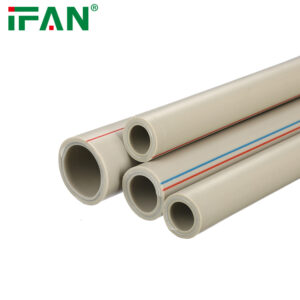

Gray PPR-AL-PPR Pipe

- PPR Pipe

PPR Glass Fiber Tube

- PPR Pipe

PPR Aluminum Plastic Pipe

- PPR Pipe

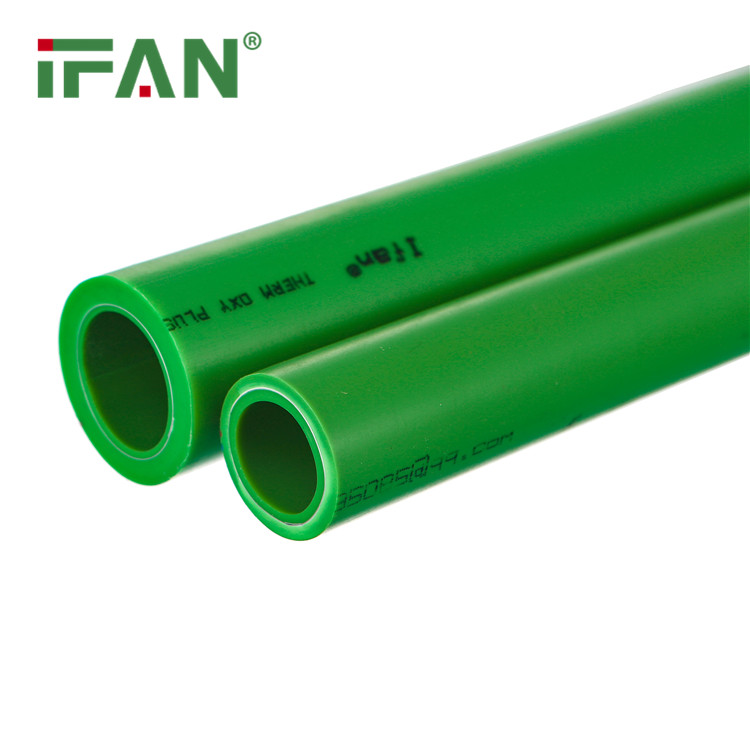

Green PPR Pipe

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US