Introduction

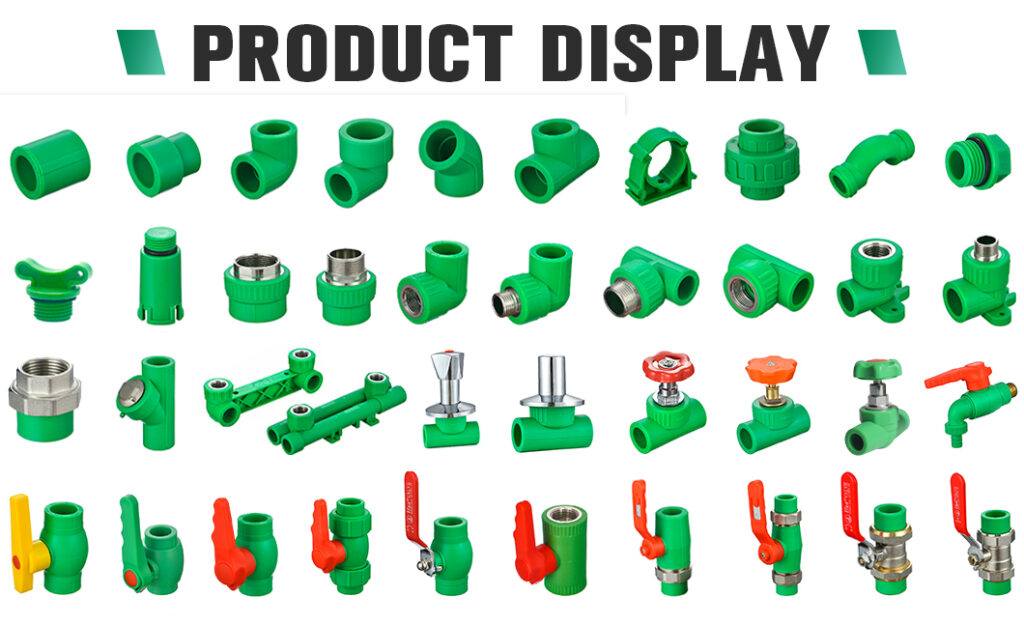

The Comprehensive Guide to Sunplast PPR Pipe Fittings in the Piping Industry: Applications, Benefits, and Installation Tips

In the world of modern plumbing and piping systems, Sunplast PPR (Polypropylene Random Copolymer) pipe fittings have gained widespread popularity. These versatile and durable components play a crucial role in various applications across the piping industry. In this comprehensive guide, we will delve into the applications, benefits, and installation tips for PPR pipe fittings, shedding light on their significance in the field of plumbing and piping.

Understanding PPR Pipe Fittings

1.1 What Are Sunplast PPR Pipe Fittings?

PPR pipe fittings, short for Polypropylene Random Copolymer pipe fittings, are essential components in plumbing and piping systems. They are made from a type of thermoplastic polymer, polypropylene, that combines exceptional strength, durability, and chemical resistance.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our FacebookWebsite: www.facebook.com.

1.2 Properties of PPR Pipe Fittings

PPR pipe fittings offer various properties that make them ideal for use in the piping industry. These properties include high-temperature resistance, corrosion resistance, smooth interior surfaces, and long-term durability.

Applications of PPR Pipe Fittings

2.1 Residential Plumbing

Sunplast PPR pipe fittings are widely used in residential plumbing systems due to their excellent performance characteristics. They are used for hot and cold water supply, as well as heating systems. Their resistance to corrosion and scale buildup ensures a long service life.

2.2 Commercial and Industrial Piping

In commercial and industrial settings, PPR pipe fittings preferred for their ability to handle high-pressure applications. They find use in factories, hotels, and commercial buildings for both potable water supply and various industrial processes.

2.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often require materials that can withstand varying temperatures and pressures. PPR pipe fittings are a reliable choice for HVAC systems due to their high-temperature resistance and low heat conductivity.

2.4 Chemical Processing

PPR pipe fittings can be found in chemical processing plants where resistance to a wide range of chemicals is crucial. Their chemical inertness makes them suitable for conveying acids, alkalis, and other corrosive substances.

Advantages of Using PPR Pipe Fittings

3.1 Durability and Longevity

One of the most significant advantages of PPR pipe fittings is their durability. They have a long service life, often exceeding 50 years, making them a cost-effective choice for both residential and industrial applications.

3.2 High-Temperature Resistance

PPR pipe fittings can withstand high temperatures without warping or deforming. This property is vital in hot water distribution systems, as well as industrial applications with elevated temperatures.

3.3 Corrosion Resistance

The corrosion resistance of PPR pipe fittings is paramount, especially in applications involving harsh or corrosive substances. They do not rust or deteriorate over time, ensuring a reliable flow of fluids.

3.4 Low Thermal Conductivity

PPR pipe fittings have low thermal conductivity, which helps in maintaining the temperature of the transported fluids. This is particularly beneficial in hot water supply systems, where heat loss minimized.

Installation Tips for PPR Pipe Fittings

4.1 Proper Jointing Techniques

To ensure leak-free connections, it is essential to use the correct jointing techniques for PPR pipe fittings. This typically involves heat fusion, which fuses the pipes and fittings together, creating a seamless and strong connection.

4.2 Tools and Equipment

The right tools and equipment are crucial for a successful PPR pipe fitting installation. These include a PPR pipe cutter, a fusion welding machine, and proper safety gear. It’s essential to follow manufacturer recommendations for tool usage.

4.3 Preparing Pipes and Fittings

Before installation, the pipes and fittings should be prepared properly. This includes ensuring clean, burr-free cuts and marking the insertion depth for the fittings. Cleanliness and precision are key to a successful installation.

4.4 Pressure Testing

After installation, pressure testing should performed to check for any leaks or weaknesses in the system. This ensures the integrity of the piping system and provides peace of mind to both installers and end-users.

Environmental Considerations

5.1 Sustainability

PPR pipe fittings known for their eco-friendliness. They are recyclable and have a lower carbon footprint compared to some other piping materials. This makes them a sustainable choice for environmentally conscious projects.

5.2 Reduced Energy Consumption

The low thermal conductivity of PPR pipe fittings leads to reduced energy consumption in heating and cooling systems. This not only saves money but also reduces greenhouse gas emissions.

Conclusion

Sunplast PPR pipe fittings have become a staple in the piping industry due to their versatility, durability, and numerous advantages. Whether in residential plumbing, industrial applications, HVAC systems, or chemical processing, these fittings provide reliable and long-lasting solutions. By following proper installation techniques and considering their environmental benefits, PPR pipe fittings continue to play a vital role in shaping the future of piping systems. Embrace the versatility and durability of PPR pipe fittings to ensure efficient and reliable fluid conveyance in your projects.