Both PPR pipes and HDPE pipes are common pipe materials, which have their own advantages and disadvantages in different usage scenarios and requirements. In daily life, we must make choices according to specific situations to meet actual needs. Next, I will give you a detailed introduction and make selection suggestions from the aspects of material performance, application scenarios, construction, and price.IFAN Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

Comparison of material properties

The full name of the PPR tube is polypropylene random copolymer eutectic tube, which is a kind of polymer material, which has the characteristics of corrosion resistance, high-pressure resistance, heat insulation, sound insulation, no pollution, and easy installation. PPR pipe has strong high-temperature resistance and can withstand high-temperature environments up to 95°C. At the same time, the PPR pipe has good toughness and impact resistance, is not easily damaged by mechanical force, and has a long service life.

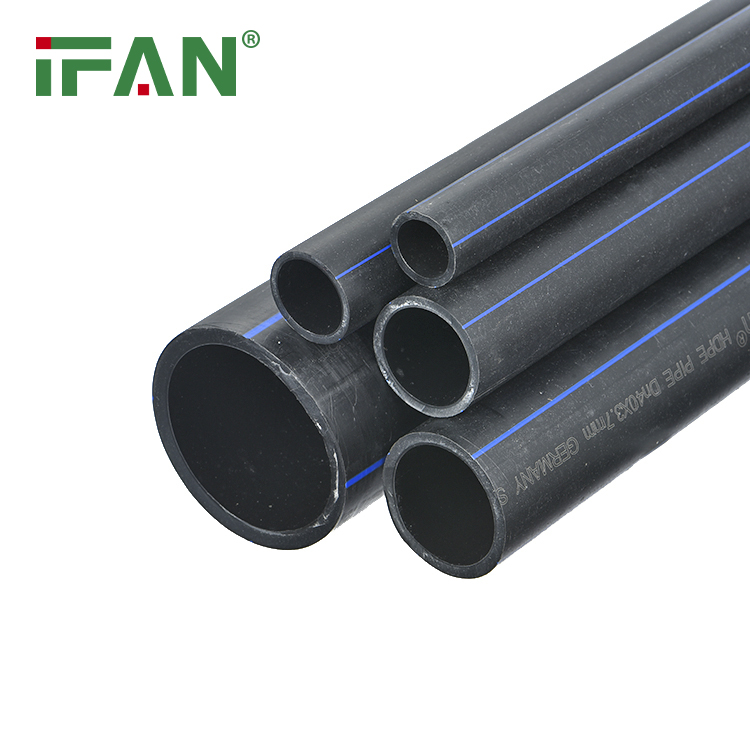

The full name of HDPE pipe is high-density polyethylene pipe, which is also a kind of polymer material. It has the characteristics of corrosion resistance, high-pressure resistance, high tensile strength, good impermeability, and low cost. The high-temperature resistance of HDPE pipes is weak, and generally can only withstand temperatures below 60°C. However, HDPE pipes are very flexible, very impact resistant, soft and easy to bend, and have a long service life.

On the whole, PPR pipe has excellent high-temperature resistance and toughness and is easy to construct and install, but the price is relatively high; HDPE pipe has the characteristics of good impact resistance and flexibility, and the use cost is low.

Comparison of application scenarios

PPR pipes are widely used in household and industrial piping systems, including hot and cold water pipes, floor heating systems, solar pipes, air-conditioning pipes, chemical delivery pipes, and other fields. Because of the high-temperature resistance and strong corrosion resistance of the PPR pipe, it is especially suitable for use in high-temperature and high-pressure environments.

HDPE pipes are mainly used in urban water supply, gas transportation, oil field pipelines, drainage pipelines, communication cables, and other fields. Due to its high tensile strength and easy construction, HDPE pipe can transport liquid or gas over a long distance and is widely used.

Construction and price comparison

Since the connection method of the PPR pipe is a hot-melt connection, special equipment is required for installation, and the construction is relatively complicated. The connection method of HDPE pipe is electrofusion connection or spiral connection, which is simpler and faster. At the same time, the price of PPR pipe is higher than that of HDPE pipe, and the price of HDPE pipe is relatively low.

Suggested choice

When selecting pipelines, comprehensive consideration should be made based on actual needs and performance characteristics. If it needs to be used in high-temperature and high-pressure environments, you should choose a PPR pipe; if you need to use it in the scene of long-distance transportation of liquid and gas, you should choose an HDPE pipe. It should be noted that when choosing a pipe, factors such as the brand, quality, and safety of the pipe should also be considered, not limited to the material itself.

To sum up, both PPR pipe and HDPE pipe are excellent pipe materials, which can meet the needs of different scenarios. In daily life, appropriate piping materials should be selected according to actual needs and characteristics. Pipeline selection is not just about material selection, but factors such as brand and quality also need to be considered to ensure the service life and safety of pipeline materials.