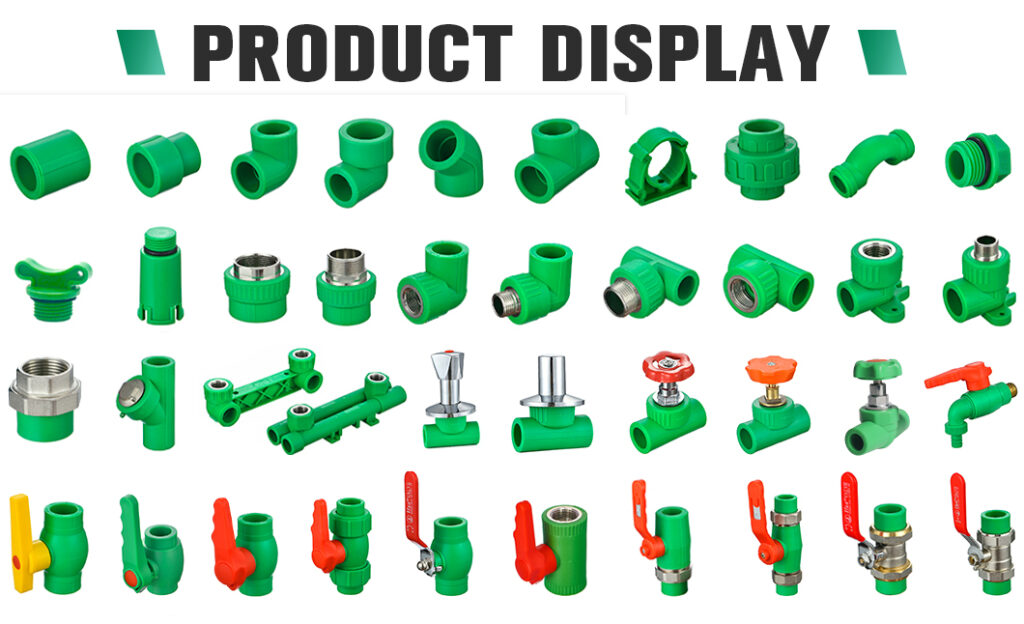

PPR Pipe Fittings

The Connectors Enabling Modern Plumbing Systems

Polypropylene random copolymer (PPR) has rapidly gained popularity as a plumbing pipe material thanks to its strength, corrosion resistance, and ease of installation. PPR pipe fittings serve the critical role of joining pipes to create complete water service systems. This article provides an in-depth look at PPR fittings.IFAN factory with 30+ years of manufacturing experience supports color/size customization and free samples. Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

What are PPR Pipe Fittings?

PPR fittings are components used to connect pipes, change direction, branch lines, alter sizes, and adapt to other parts of a piping network. They allow assembling full plumbing systems out of PPR pipe sections.

PPR fittings are made from the same engineered thermoplastic material as the pipes. This ensures optimal bonding and performance longevity when fittings are joined to pipe segments.

PPR fittings provide either permanent cold-pressed joints or temporary threaded connections. Standard shapes like elbows, tees, and adapters accommodate various piping layouts above and below ground.

Key Attributes of PPR Fittings

Quality PPR fittings share beneficial attributes with PPR pipe that make them advantageous for plumbing systems:

- High strength – Ability to withstand pressure surges without leakage or breakage.

- Corrosion resistance – PPR fittings are inert to water exposure.

- Thermal endurance – Performance maintained through hot and cold temperature extremes.

- Flame resistance – PPR is self-extinguishing and won’t fuel fires.

- Flexibility – PPR fittings move with pipes as they expand and contract.

NSF certifies PPR fittings for contact with potable water. The neutral material does not impart tastes, odors, or contaminants to flowing water.

PPR Cold Press vs. Threaded Fittings

PPR fittings connect to PPR pipes through an innovative cold press method rather than using threads. The fitting contains an internal O-ring gasket that gets compressed around the inserted pipe when crimped with a pressing tool.

This forms a strong, permanent seal able to withstand years of pressure and temperature changes without leaking or loosening. Cold-pressed PPR joints allow fast, simple PPR connections without glues, solvents, or exposed heat.

Proper Cold Pressing Technique

Correct cold pressing procedures for PPR fittings include:

- Cutting pipe ends squarely and deburring

- Cleaning pipe and fitting surfaces before assembly

- Inserting pipe fully until it bottoms out in the fitting socket

- Using proper press tools to completely compress the fitting

Following manufacturer instructions prevents distorted or over-compressed fittings. Hydraulic press tools crimp a full 360 degrees around the fitting for reliable sealing.

PPR Transition Fittings

While PPR plumbing systems utilize PPR fittings for most connections, adapters are needed to integrate components of other materials:

- PPR x copper adapters

- PPR x galvanized steel nipples

- PPR x PVC/CPVC couplings

- PPR x female threaded valves, pumps, or equipment

Having suitable transition fittings prevents limiting PPR to only certain sections of plumbing and expands integration capabilities.

Proper Design and Installation

PPR fittings systems require proper planning and installation to fulfill performance expectations:

- Pipe routing optimized for efficient flow to all endpoints.

- Positions of equipment, valves, and accessories marked.

- Hanger positions and anchor points are indicated per code.

- Provisions for thermal expansion and contraction.

- Allowances for pressure testing to validate water-tight joints.

The following specifications preserve fitting integrity for decades of leak-free service.

The Advantages PPR Fittings Provide

PPR fittings present numerous advantages over traditional metal fittings in plumbing systems:

- Faster, simpler installation using pressed connections.

- No leakage risk from failed threads or cracked castings.

- Maintains smooth water flow without mineral buildup.

- Resilient against tremors and earthquakes.

- A long lifetime without corrosion from water exposure.

For both residential and commercial plumbing, PPR fittings deliver reliable, superior performance compared to metals. They are an indispensable component enabling high-efficiency PPR piping networks.

IFAN

IFAN factory started in 1993. And IFAN has a workshop of 120000 square meters with 610 staff. IFAN can design and produce all plumbing pipe and fitting including PPR, PVC, CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting, brass fitting, brass ball valve, heating system, gas system, sanitary faucets, and hose, In the past 30 years, IFAN has never forgotten his mission-To protect health and safety. The IFAN factory uses the best materials to produce high-quality pipe and fittings with an automatic production line and high-tech quality control machines.