Types of PPR Fittings

An Overview of Polypropylene Random Copolymer Fitting Options

Polypropylene random copolymer (PPR) piping relies on the corresponding fittings to create fully functioning plumbing systems. PPR fittings come in a wide variety of types to connect pipes, alter flow, and enable system assembly. This article provides an overview of the main PPR fitting categories.IFAN factory with 30+ years of manufacturing experience supports color/size customization and free samples. Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

Definitions of PPR Fittings

PPR fittings are connectors used to join pipes, change direction, branch lines, alter sizes, and adapt to other components in PPR piping networks. They are manufactured from PPR resin to match the pipes.

Fittings create secure, watertight PPR joints able to withstand pressure fluctuations and thermal movement without leaking. Their capabilities enable assembling full PPR plumbing systems.

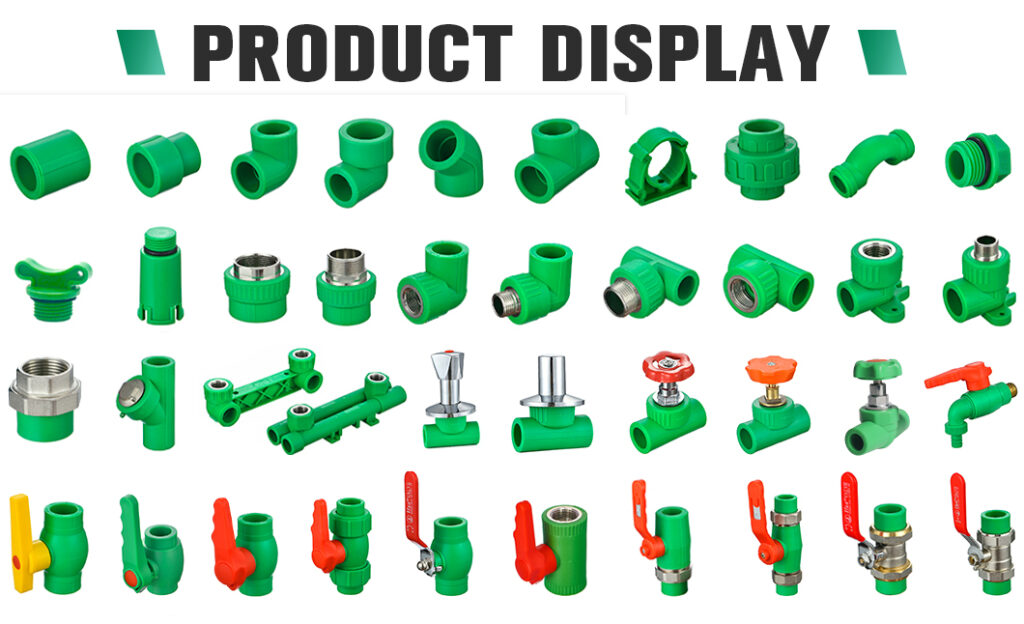

Common PPR Fitting Types

PPR fittings come in many standard configurations:

- Elbows – 90° and 45° elbows change direction on horizontal or vertical runs.

- Tees and crosses – Allow branching main lines to feed additional lines and equipment.

- Couplings and unions – Join two sections of straight pipe.

- Caps – Close off the end of a pipe.

- Adapters – Connect to other fitting materials like metal or NPT threads.

- Reducers – Transition between different pipe sizes.

- Valves – Control water flow and provide isolation points.

PPR Fitting Joint Connection Methods

PPR fittings utilize two primary methods to connect to PPR pipes:

- Cold press – Fittings compress an O-ring seal around the inserted pipe when crimped.

- Threaded – Male threaded PPR joints screw into female socket adapters.

Cold pressing provides permanent, reliable PPR joints. Threading allows reuse and interchangeability.

PPR Transition Fittings

While most PPR systems use PPR fittings, transition adapters incorporate components of other materials:

- PPR x copper – Connect to existing copper plumbing.

- PPR x galvanized iron – Interface with threaded pipes, valves, and pumps.

- PPR x PVC/CPVC – Enable connections to different plastic piping.

- PPR x PEX – Combine with PEX tubing in hydronic heating systems.

Transition fittings prevent limiting PPR to isolated system sections.

Fabricated PPR Fittings

Beyond standard fitting components, custom fabricated PPR fittings get made to order:

- Large diameter headers to supply banks of outlets.

- Multi-port tees for complex piping junctions.

- Elbows and laterals in specialty angles or dimensions.

- Valve housings and fluid control devices.

- Pump housings for fluid transfer efficiency.

Fabricated from PPR stock, CNC machined fittings optimize performance for unique applications.

PPR Outlet and Connection Fittings

PPR outlet and connection fittings enable system integration:

- Tees – Branch off main lines to feed secondary lines.

- Elbow outlets – Provide directional branches.

- Adapters – Connect PPR piping to valves, pumps, and appliances.

- Closet flanges – Interface toilet bowls to PPR drain lines.

- Ball valve adapters – Allow isolating sections of piping.

Properly installed PPR outlet and connection fittings withstand continuous pressure and flow over decades of service.

Choosing Ideal PPR Fitting Types

With a full range of options, engineers select optimum PPR fitting types to create leak-free piping networks matching projected demands. Correct fitting selection provides the connections enabling high-performance PPR plumbing.

IFAN

IFAN factory started in 1993. And IFAN has a workshop of 120000 square meters with 610 staff. IFAN can design and produce all plumbing pipe and fitting including PPR, PVC, CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting, brass fitting, brass ball valve, heating system, gas system, sanitary faucets, and hose, In the past 30 years, IFAN has never forgotten his mission-To protect health and safety. The IFAN factory uses the best materials to produce high-quality pipe and fittings with an automatic production line and high-tech quality control machines.