Brass sliding fittings

Name:Brass sliding fittings

Size:16-32mm

Brand:IFAN

Category : Click Download

Whatsapp : +86 19884503412

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

Brass sliding fittings, .these fittings are made of brass, a metal alloy composed of brass and zinc, which offers excellent durability and corrosion resistance. In this blog, we’ll delve deeper into the material, production process, types of brass sliding fittings, how to connect them, and their advantages.

Our factory

–About Zhuji Fengfan Piping Co.,.td

IFAN factory started in 1993. And IFAN has workshop 120000 ㎡with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified.

Click here view more our factory!

Material:

Brass sliding fittings are made of CW617 brass, which is an alloy composed of copper and zinc. The percentage of copper and zinc can vary, depending on the desired properties of the brass. Brass is known for its excellent combination of strength, ductility, and corrosion resistance, making it an ideal material for plumbing and other industrial applications.

Production Process:

Brass sliding fittings are manufactured through a multi-stage process that involves casting, machining, and finishing. The raw material (i.e., brass) is melted and poured into a mold to create the desired shape. Then, the casting is subjected to machining operations, such as drilling, turning, and milling, to achieve a precise fit and finish. Finally, the fittings are polished and coated to enhance their appearance and protect against corrosion.

Types

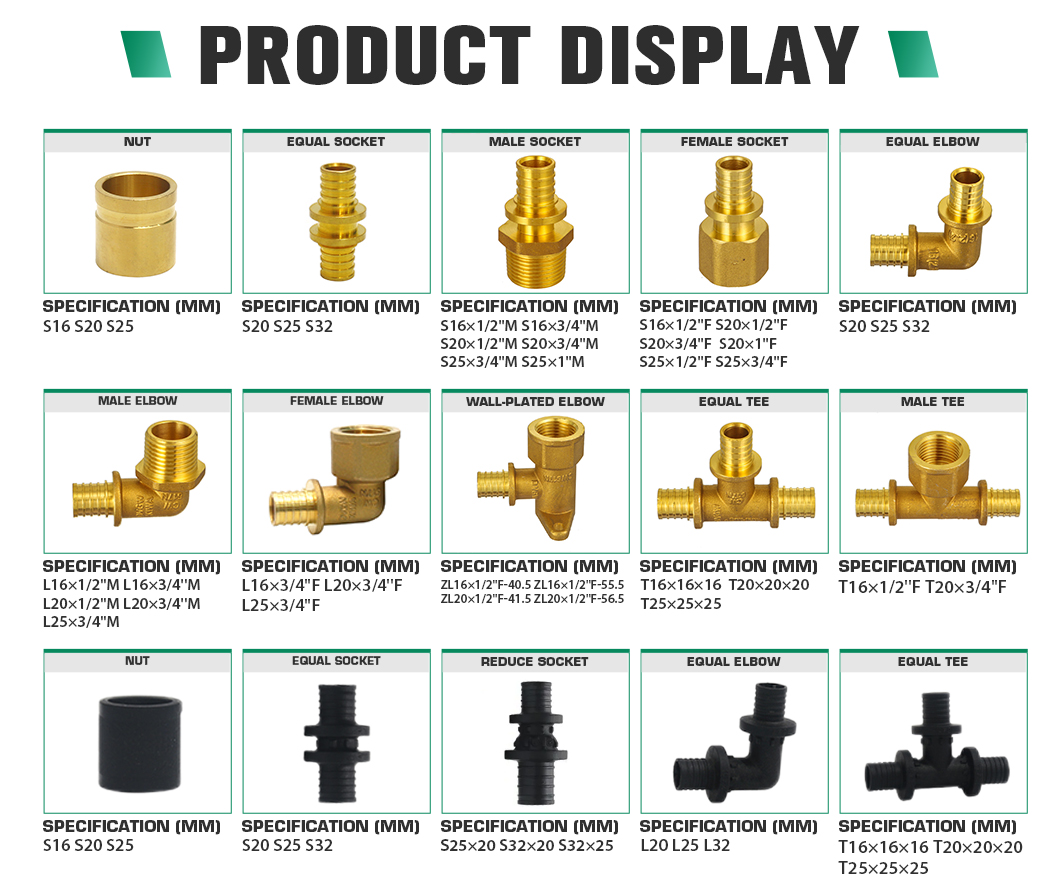

There are several types of brass sliding fittings, each designed for specific applications and piping systems. The most common types include:

– Socket/Coupling:male socket,female socket,equal socket,reducing socket

– Elbow: male elbow,female elbow,equal elbow,reducing elbow.

– Tee: male tee,female tee,equal tee.

– Nut

Click here to get product catalog!

Connecting Brass Sliding Fittings:

Here’s a step-by-step guide:

1. Cut the pipe or tube to the desired length using a pipe cutter or hacksaw.

2. Smooth the cut end with a file or emery paper to remove any burrs.

3. Slide the nut and compression ring onto the pipe or tube.

4. Insert the pipe or tube into the fitting body, ensuring it is seated firmly.

5. Tighten the nut with a wrench to create a watertight seal.

Advantages

It offer several advantages over other types of fittings, such as:

– Durable: Brass is a sturdy material that can withstand high pressure and temperature.

– Corrosion-resistant: Brass has excellent corrosion resistance and does not rust or corrode easily.

– Easy to install: it can be installed quickly and easily using basic tools.

– Versatile: there are suitable for a wide range of applications and can be used with various pipe or tube materials.

In conclusion

Brass sliding fittings are an essential component of plumbing systems, used to connect pipes or tubes with a watertight seal. They are made of brass, a durable and corrosion-resistant material, and are available in various types for different applications. By understanding how to connect and install it, you can ensure a reliable and leak-free plumbing system for your home or business.

相关产品

-

PEX Fitting

Pipe Press Fittings

-

PEX Fitting

PEX Sliding Fittings

-

PEX Fitting

PEX Slide Fittings

-

PEX Fitting

pex fittings

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US