Green PPR Stop Valve

Name: Green PPR Stop Valve

Size: 20-63mm

Material: PPR

Application: Water system

Working pressure: PN25

Sample: Free

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

IFAN green PPR stop valve is made of 100% Korean Hyosung raw material, and the valve core is made of brass. Its raw material molecules are composed of natural carbon and hydrogen elements. It is safe and reliable, which is non-toxic and environmental protection, strong corrosion resistance of pipeline ,It has not chemical influencedo on drinking water and chemicals in buildings.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

PPR water pipe valve installation guide

1. Before installing the PPR valve, carefully check whether the model and specification of the PPR valve used are consistent with the design.

2. According to the model and factory instructions of the PPR valve, check whether the valve can be used under the required conditions.

3. Pipe cutting. The bayonet of the pipe scissors should be adjusted to match the diameter of the pipe to be cut, and the force should be uniform when the pipe is rotated and cut. When the pipe is broken, the section should be perpendicular to the pipe axis.

4. Pipe connection. It is the most reliable way to connect PPR water pipes and pipe fittings by hot melting, which has good airtightness, convenient operation and high interface strength. Remove foreign matter from pipes and fittings before connecting. The melting time and depth of pipes and fittings should meet the requirements. Do not rotate while hot soldering. When connecting pipe fittings with wires, the raw material tape should be wrapped to ensure airtightness.

5. The pipe is fixed. In order to avoid resonance due to water pressure, all water pipes must be fixed with pipe clamps. For pipes with a pipe clamp spacing of 40-50cm and an outer diameter of less than 25mm, pipe clamps should be installed at corners and water meters, 10cm from the pipe end . If it is a water pipe that runs through the groove, the thickness of the mortar filling is greater than 10cm.

PPR stop valve installation precautions

1. The bolts on the flange and bracket are indispensable, and the thread should be complete without any looseness.

2. If the fastening nut on the handwheel is loose, tighten it in time to avoid loss of the handwheel and nameplate or wear of the connection. If the handwheel is lost, do not use an adjustable wrench to replace it, it should be equipped in time.

3. The scale on the valve should be accurate, complete and clear.

4. There should be no dents or cracks in the insulating sleeve.

5. The bonnet, lead seal, pneumatic accessories, etc. should be intact.

6. For valves in an environment that is easily polluted by dust, rain, snow, sand and other dirt, a protective cover should be equipped on the valve stem.

7. The packing gland should not be deflected or have no pre-tightening gap.

8. Do not stand, beat or support heavy objects on the valve during operation, especially non-metallic valves and cast iron valves.

相关产品

-

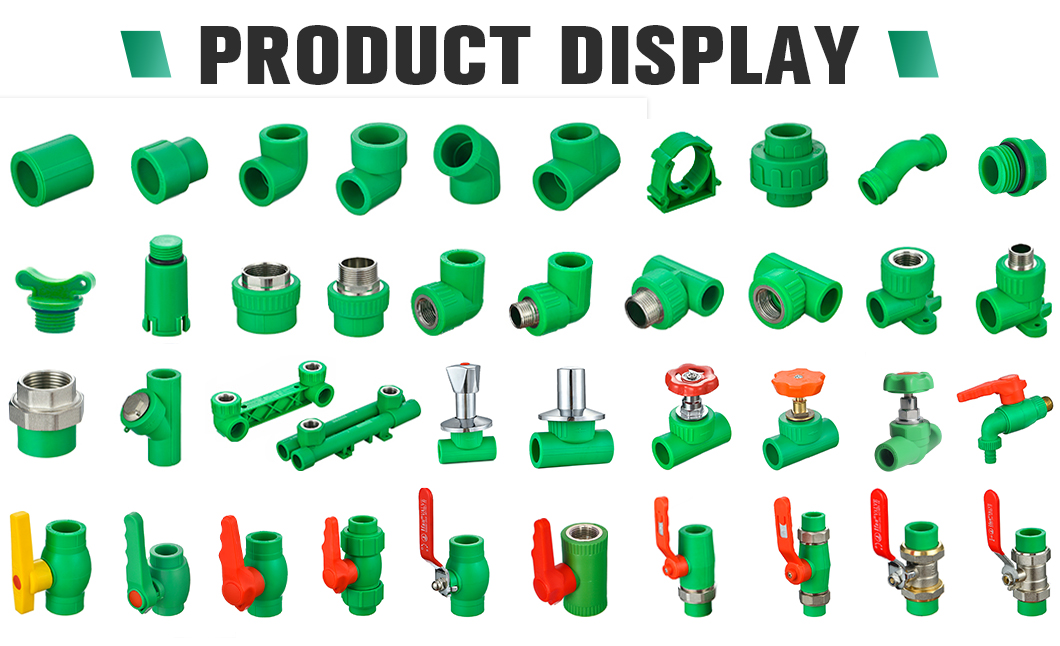

PPR Fitting

White PPR male Elbow With Seat

-

PPR Fitting

WHite PPR Male Tee

-

PPR Fitting

PPR End Cap

-

PPR Fitting

PPR Elbow Fittings

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US