Craftsmanship

What Is Brass Fittings? The manufacturing process of brass fittings is mainly divided into three steps: casting, machining, and surface treatment.IFAN Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

Casting:

Brass pipe fittings are made by the casting process. First, a mold is made according to the desired shape and size of the product, and then molten brass is poured into the mold and allowed to cool to form a product of a specific shape.

Processing:

After the casting is completed, the product needs to be processed. Processing is mainly divided into two aspects. The first is finishing and grinding, that is, polishing the surface of the product through mechanical equipment to remove burrs and blemishes on the surface to make it smoother. The other is forging, where the cast product is heated (gray fire, yellow fire, white fire) and then forged with force to increase the strength of the product and reduce defects in the product.

treatment:

Surface treatment can give brass fittings a better appearance and better oxidation resistance. Surface treatment mainly includes chrome plating, nickel plating, copper plating, etc.

Regular size

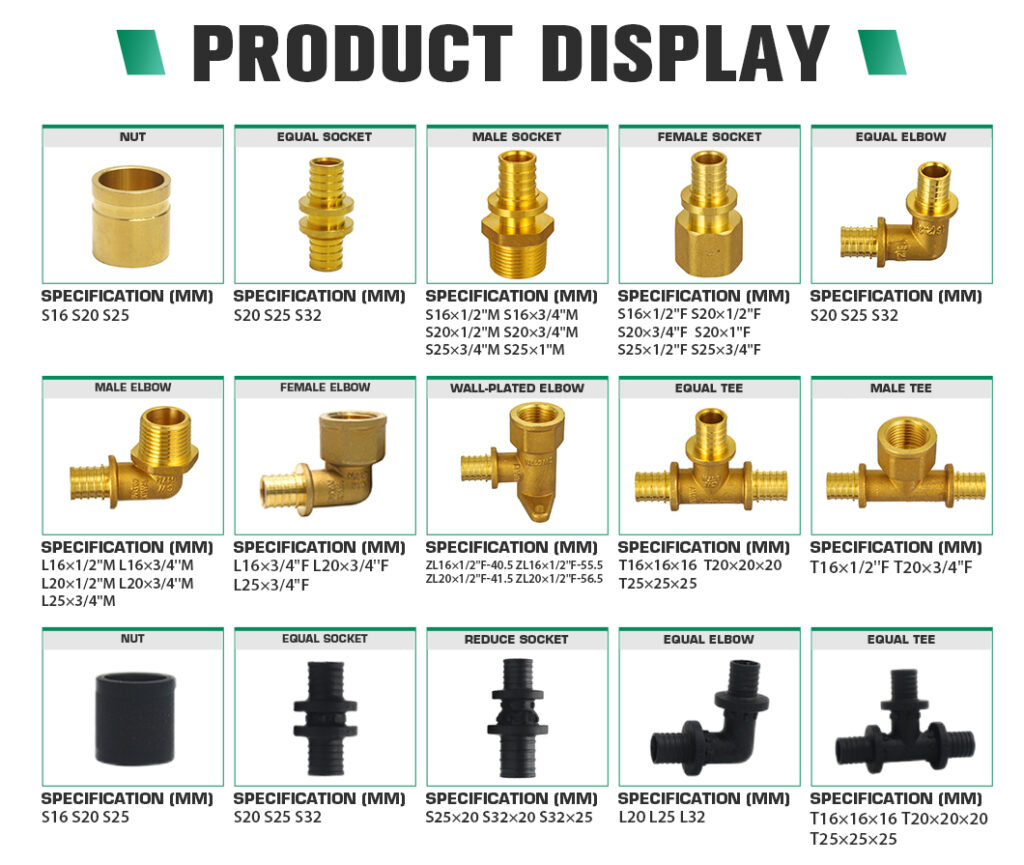

Brass pipe fittings come in a variety of sizes, generally divided into straight pipes, elbows, tees, crosses, etc.; in terms of pressure, there are low pressure (PN16) and high pressure (PN25). The conventional size of brass pipe fittings in the market is DN8-DN100, among which DN8, DN10, DN15, etc. are commonly used in household water piping systems; DN25, DN32, DN40, DN50, etc. are commonly used in water pipes in commercial places, public places and industrial systems.

Advantages of Brass

Brass has many advantages as a premium material.

Corrosion resistance: Brass has strong corrosion resistance and is not easily weathered by seawater, rain, etc. Therefore, brass pipe fitting is very suitable for outdoor use and is not easily affected by the environment.

Thermal conductivity: Brass is an excellent thermal conductivity material, better than some other metals, so brass pipe fitting can work at high temperatures and can also be used as heat sinks.

Easy installation: The installation of brass pipe fitting is very simple and does not require special techniques such as welding. Simply tighten the clamps by hand.

Toughness: Since brass has relatively good toughness, brass pipe fitting is not easy to break or crack during installation or operation.

Wear resistance: Brass pipe fitting has very good wear resistance and can be used for a long time without cracking or breaking.

Features

As a connecting part of a piping system, brass fitting have the following characteristics:

High reliability: Due to the fine processing technology of brass pipe fitting, the product has high reliability and can run stably for a long time.

High-temperature resistance: Brass pipe fittings can work at high temperatures, and it is not easy to deform and foam due to excessive temperature.

Pressure resistance: brass pipe fitting has good pressure resistance, and it is not easy to cause accidents such as explosions due to excessive internal pressure of the pipe.

Corrosion resistance: Brass pipe fittings have good corrosion resistance and can be used for a long time in water and atmosphere.

Beautiful appearance: Brass pipe fittings have smooth surfaces, bright colors, a beautiful appearance, and an elegant atmosphere.

preservation method

Before use, the brass fitting need to be cleaned (can be cleaned with a soft brush) to remove dirt and oil.

When storing brass fittings, avoid direct sunlight to avoid oxidation or discoloration caused by exposure.

Brass fitting should not be placed in humid or high-temperature places.

For brass pipe fitting with a surface treatment such as copper plating and nickel plating, the surface should be prevented from abrasion, otherwise, it may affect the aesthetics and reduce the product life.

Brass pipe fittings should avoid excessive bending and extrusion during installation and operation, otherwise, it will cause cracks or deformation.